Process plays factor in determining ways to protect workers

While machinery makers are continually offering new and improved safety features on their equipment, much of the responsibility for worker safety falls on the processing companies themselves.

However, some research indicates that not all processors are taking advantage of optional safety devices or properly using the safety features they do have. According to a recent study of a small number of Canadian injection molding factories, workers are often lax about safety practices during maintenance procedures.

For the study, researchers at Canada's Institut de recherche Robert-Sauvé en santé et en sécurité du travail (IRSST) visited six Canadian factories with injection molding machines and peripheral equipment. They found that out of 43 risk-reduction means identified for the study, only five were used at all of the plants. However, most of the plants did have at least one risk-reduction method in place for all identified hazardous situations.

In examining incident reports, the researchers found some severe lapses in use of protective devices.

"For example, in many cases, there were no guards or else they were damaged, not functioning or incompatible with the work situation," said Yuvin Chinniah, an engineer and the lead researcher.

SAFETY NEEDS DEPEND ON MACHINERY

IRSST's study focused on injection molding plants, but other processes have their safety issues, too. Plant managers should be aware of what machinery and equipment in their plants pose the greatest risks.

For example, the cutting blades in pelletizers and granulators are among the greatest safety hazards for workers, said Dave Miller, GM for size reduction at auxiliary equipment maker Conair Group and Republic Machine, a maker of size-reduction equipment.

"The rotor knives move at a high rate of speed, and you are feeding the plastic into the machine; it can be one of the most dangerous areas on the plant floor," Miller said. "Even when turned off, the machines still have plenty of stored inertia — it can take 5 to 30 seconds for the rotor to stop spinning."

It's important for processors to work with their equipment suppliers to ensure the manufacturers can meet their requirements while staying within safety guidelines.

"Some customers come to us with some crazy applications," Miller said.

For example, some clients have asked for material to come off an extruder or secondary trimmer at a low height. The lower the machine is to the ground, the harder it is to keep a worker safe from all of the moving parts, he said.

"Companies have taken a hard look at safety. Liability insurance is high. It's in our best interest to make the machines safe," he said. Miller is one of the volunteers who will help the Plastics Industry Association (PLASTICS) review and update its safety standards for granulators and pelletizers this year.

For sheet extruders, chrome roll stands pose a particular risk due to their pinch points, especially where the primary rollers come together, said Tom Limbrunner, senior VP of applications and technology for Processing Technologies International, a supplier of extrusion systems.

"Providing safety as well as reasonable access is often a challenge," Limbrunner said. While machine manufacturers ensure their designs meet American National Standards Institute (ANSI) and PLASTICS standards, older machines can present safety challenges.

"For example, I see various customers with winding equipment that has a complete lack of guarding, as well as an absence of interlocks," Limbrunner said. Machines with interlocked guards will not run unless the guards are in place.

Some older machines can be retrofitted with additional safety features, Limbrunner said. However, processors should consider replacing older systems, as the safety retrofits tend to be more expensive the older the machine is.

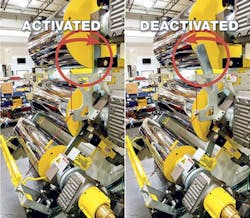

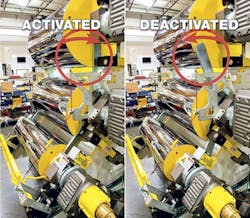

For blow molding companies, taking advantage of new technology can ensure that machine operators won't bypass safety systems. Safety PLCs, which are used on doors that close to prevent access to the inside of the machine, are much safer than hard-wired switches, said Chuck Flammer, VP of sales for Kautex Machines and chairman of PLASTICS' blow molding safety subcommittee. They are available on Kautex blow molding machines, as well as those from other manufacturers.

"Before safety PLCs, you would have a switch that cut power to the hydraulics. Hard wiring is cheaper, but safety PLCs offer more protection because you really can't defeat them," he said. Machine operators have been known to alter the wiring of switches, creating unsafe operating conditions. With the newer technology, a device on the door has to connect with another device on the door frame, like a key in a lock. If the devices don't match up, the machine can't operate.

Safety PLCs have been available in Europe for about a decade, Flammer said, but were slower to come into use in the U.S. because the new technology wasn't recognized by the relevant ANSI safety standard until it was updated in 2014.

Phillip Britt, correspondent

For more information

Conair Group,Cranberry Township, Pa., 724-584-5500, www.conairgroup.com

Institut de recherche Robert-Sauvéen santé et en sécurité du travail,Montreal, 514-288-1551, www.irsst.qc.ca/en

Kautex Machines Inc.,North Branch, N.J., 908-252-9350, www.kautex-group.com/us-us

Processing Technologies International LLC,Aurora, Ill., 630-585-5800, www.ptiextruders.com

Republic Machine,Louisville, Ky., 502-637-6778, www.republicmachine.com