Patent Report: Machine makes containers upstream

Immobiliare Mondini SpA, Brescia, Italy, has applied for a patent for a thermoforming machine that can make containers directly upstream of food-filling processes. It claims the invention would be an improvement over existing machines because it is versatile enough to handle containers of different sizes and shapes.

The company's application states that it aims to improve upon earlier equipment and "provide an apparatus for thermoforming plastic containers that makes size change-over operations for making containers having different shapes and/or sizes extremely simple." The ability to do so, it says, is "thanks to the fact at least most of the flat sheets necessary are obtained when needed directly from a web of thermoformable plastic material." The machine employs a rotor to rotate molds from a receiving station, where a flat sheet of thermoformable material is applied to the forming station, where a shaped mold is pressed into the sheet.

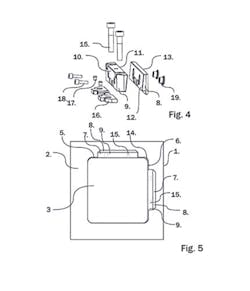

According to the application, one innovative feature of the machine is that the heating elements used to soften the plastics and the closing elements operate in conjunction with one another, but independently, moving relative to each other between a coupled position and an uncoupled position.

"When they are in the coupled position, the heating body is coupled to the resting surface and the heating body can heat the closing element (mainly by contact, that is to say thermal conduction)," the patent states. "In contrast, when they are in the uncoupled position, the heating body is uncoupled from the resting surface and away from it."

Such an arrangement allows multiple thermoformers to operate simultaneously using a rotary system.

In addition to the innovative heating and closing elements, the thermoformers proposed by Immobiliare could be equipped with innovative, interchangeable molds, allowing for the production of different containers. In one variation on the proposed invention, "the shaped mould (or moulds) is made in one piece with a single supporting element which can be mounted on and demounted from the rest of the apparatus in a similar way to an extractable drawer," the patent states.

To accommodate the needs of containers of varying shapes and sizes, the patent says multiple cutting units may be needed.

Patent application 20170320260; published Nov. 9

In other patent news:

Injection mold. Lego A/S, Billund, Denmark, has patented a type of injection mold that features an outer frame with a space for mounting one or more exchangeable mold inserts. Each mold insert is secured in the frame by at least one mounting fitting that has a support plate corresponding to a recess in the mold insert. The fitting also has two wedge-shaped parts that are secured to each other. The support plate ensures that the insert will not fall out. The purpose of the invention is to lower the risk of losing mold inserts and also to reduce wear on the mold and mold parts, according to the patent."A particularly simple handling of the mounting fitting is accomplished by the two wedge-shaped fitting parts being secured to each other in such a manner that they can be shifted relative to each other," the patent said. "This handling is further facilitated by a preferred embodiment, whereby the support plate comprises at least one elastic holding element which is configured so as to be deformed elastically by introduction of the support plate into the recess."Patent 9,833,936; issued Dec. 5

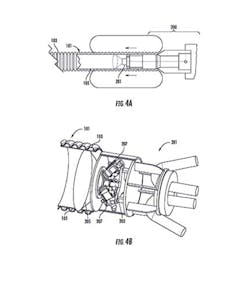

Additive manufacturing. Thermwood Corp., Dale, Ind., has been granted a patent for a method and apparatus that addresses problems with thermal expansion and contraction during near-net-shape, extrusion-based printing of molds and tooling components made of polyphenylene sulfide (PPS).A maker of CNC routers and large additive machines, Thermwood notes that 3-D printing using PPS and reinforcing fibers can be less time-consuming and costly than traditional methods of making molds and tooling for industries such as aerospace. However, the material expands when heated and contracts when cooled — often at uneven rates, with more dramatic thermal changes taking place perpendicular to the direction of the fiber.To overcome these problems, Thermwood proposes combining an extruder, which deposits successive layers of near-net-shape parts, with a CNC machine and trimming gantry with an attached touch probe or surface scanner, for finishing and measuring parts. "Once part has cooled to room temperature," the patent states, "trimming gantry may be used with an attached router to machine and/or trim printed part to final net shape."Thermwood's patent suggests integrating the CNC machine with the touch probe, so that measurements taken by the probe can be automatically compared against the reference model of the intended part.Once a mold or mold component has been printed, trimmed and measured, the patent says that it should be heated to its anticipated operating temperature, then re-measured. Using data from this mold trial, the control for the CNC can calculate a new tool path; as the patent states, "The CNC control may then be instructed to run a second trimming program."Patent 9,833,986; issued Dec. 5

Mold temperature control. Compagnie Plastic Omnium, Lyon, France, has proposed a device that uses a laser beam to control the temperature of an injection or compression mold. The device includes at least one radiation head and a heat-exchange plate in contact with part of the mold wall. The radiation head emits a beam toward the heat exchange plate, which is made of a conductive material. The device has advantages over traditional mold-heating methods, including improved energy efficiency and the ability to use simpler mold designs.Using the device "avoids having to provide a complex network of pipes to cool the entire mould. Simplifying this network, or even not using such a network, reduces the investment costs, assembly and disassembly time, and also reduces the size of the blocks forming the mould," the patent application states.Patent application 20170334097; published Nov. 23

In-line pipe inspection. Prinsco Inc., Willmar, Minn., has patented an inspection system for scanning and recording defects in the smooth inner wall of dual-wall corrugated plastic pipe during the manufacturing process. The system includes a pipe corrugator and a conical laser-pattern generator that passes through the pipe to complete a 360-degree scan of the inner surface. It also has three precisely aligned cameras to record the scans. The patent states, "With this camera configuration, comprehensive 3-D coverage of the inner wall may be recorded and analyzed for manufacturing defects as the dual-wall pipe is being manufactured, thus ensuring structural integrity of the manufactured pipe." The device notifies the corrugator operator of any defects.The system is especially useful for inspecting a type of dual-wall corrugated pipe that can be coiled, in which the inner pipe is extruded from a blend of TPE and a thermoplastic resin for enhanced longitudinal flexibility. Such pipe is used for drainage in agriculture.Patent 9,764,506; issued Sept. 19