Desktop Metal's 3-D printer can make mold components

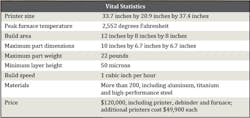

DM Studio Desktop Metal's new printer, which extrudes bound metal rods to produce near-net-shape parts, can be used by makers of mold components. It works in conjunction with a furnace with closed-loop thermal control that uniformly heats parts to just below their melting point.

What's new? The system, which uses a proprietary technology the company calls Bound Metal Deposition printing. It began shipping in August.

Benefits Ease of use, precision and cost-competitiveness. Designed using a cloud-based architecture, the system allows users to go directly from a CAD file to a part. It employs automated bed leveling and ball screws rather than belts, and produces high-quality parts, with densities of between 96 percent and 99 percent, depending on the alloy. According to the company, the system's printing technology is safer than other metal 3-D printing processes.

Desktop Metal Inc., Burlington, Mass., 978-224-1244, www.desktopmetal.com