Printer makers power up enhancements, new models

As 3-D printing continues to make inroads in commercial and industrial applications, printer manufacturers are responding with improved software, upgraded components and completely new machines.

MARKFORGED

In August, Markforged, a manufacturer of industrial-grade printers, released new models as alternatives to the company's top-of-the-line X7 printer. That unit's $69,000 price is beyond the reach of some companies, said Jon Reilly, product VP.

Designed for making strong parts, such as tooling, fixtures, prototypes and functional end-use parts, the company's printers use composite materials.

The new models include the X3, priced at $36,990, which uses a fused-filament-fabrication process to print with Onyx, a carbon-fiber-filled nylon that can withstand high temperatures. A second new printer, the X5, can further reinforce the Onyx material with a strand of continuous fiberglass for parts that are 19 times stronger and 10 times stiffer than traditional plastics, the company said. It costs $49,990.

The other facets and dimensions of the printers are the same. Each printer has a build volume of 12.9 inches by 10.6 inches by 7.8 inches, a footprint of 23.9 inches by 19 inches by 35.9 inches, and weighs 150 pounds. Companies that start with a lower-priced printer have the option to upgrade the interior components to provide higher-end capabilities.

"We wanted to enable companies to be able to upgrade without the need to buy an entirely new printer," Reilly said.

All three printers offer a built-in micrometer to automatically scan the print bed with 1-micron accuracy to generate a contour map of the surface. Calibrating the measurements with extrusion readings enables users to correctly set nozzle height and active topology adjustment.

PHOTOCENTRIC

Dom Mahoney, president of Photocentric Inc. USA, ticks off a number of areas for improvement for 3-D printers, including speed, size, cost and accuracy. His company, which began building printers a few years ago based on its experience as a resin supplier, is in the midst of launching bigger machines based on its Daylight Polymer Printing (DPP) technology.

"It's a fast-moving, dynamic, evolving industry," Mahoney said, "and we're trying to stay ahead of our competition by working to develop better, faster, quicker, more accurate machines and resins."

Light-sensitive resins, like those used in DPP, have photoinitiator compounds within them that harden when exposed to specific wavelengths.

According to Mahoney, many are reactive to ultraviolet light; however, the material supplied by Photocentric uses natural light supplied by LCDs.

"This is uniquely different because it reacts to daylight-frequency light," he said. This makes it easy for Photocentric to scale up its printers because all it has to do, Mahoney explained, is use a larger light source.

"It's just a question of using a bigger screen," he said.

In May, the company began shipping its large-format Liquid Crystal Pro, which has a build volume of 18.5 inches by 9.4 inches by 13.4 inches, with layer thicknesses of 50 or 100 microns. It measures 33 inches by 29 inches by 20 inches.

It is targeted at designers, engineers and makers of industrial prototypes, and is also suited for producing batches of small parts. It costs about $4,300.

In addition to jewelry makers and dentists' offices, Photocentric's customers include some large-scale manufacturers, such as automotive-parts makers, Mahoney said. Because Photocentric makes its own printers and resins, it offers unique benefits. "One of the advantages is, cost-wise, we're very competitive," he said.

Photocentric's recent updates include a stronger resin vat and improvements to the light screen supplied with its Liquid Crystal HR printer. Priced at about $1,900, the high-resolution, medium-format printer features a build volume of 7.7 inches by 5.7 inches by 9.8 inches.

Mahoney said the company continues to work on the chemistry of its resins, as well as the mechanics of its machines, to improve printing speed. Even bigger models will be released next year, he said.

CARBON

Like Photocentric, Carbon makes printers that use light to harden resins. Recently, it launched a resin-dispensing accessory for its SpeedCell system, which combines a part-washing system with its M-series 3-D printers. The new device — called the MMD for meter, mix and dispense — allows for the proper dispensing of material in bulk quantities into its M-series printers.

Developed in conjunction with Henkel Adhesive Technologies, a Rocky Hill, Conn., supplier of adhesives, sealants and coatings, the table-top unit offers a variety of benefits. The ability to process bulk materials gives users the opportunity to lower their resin costs. Also, the device provides fast dispensing, and thorough and repeatable mixing, according to the company.

So far, the company said, it is focusing its marketing efforts regarding MMD on use with rigid PU (RPU). However, resins from Carbon's other material lines could eventually be offered for use with the MMD.

The MMD is part of a strategy Carbon announced in September to help large manufacturers better manage material costs. The company now is supplying its RPU in MMD-compatible bulk packaging, resulting in a 40 percent price reduction. The company said it will be able to further reduce costs for RPU over the next year.

"This production-volume materials approach will allow us to ensure that our partners like Adidas, which will be printing thousands or millions of parts, can do so economically compared to other manufacturing methods such as injection molding," CEO Joseph M. DeSimone said.

Designed for rapid production, the SpeedCell system has been available since the spring. Its part-washing system removes support structures and provides optimal cleaning and easy finishing of parts made by its proprietary Continuous Liquid Interface Production (CLIP) technology, which uses ultraviolet light to cure photopolymer resin.

Two printers are available for use in a SpeedCell, including the M2, which offers a build volume of 7.4 inches by 4.6 inches by 12.8 inches. Both the M2 and its smaller sister, the M1, offer resolutions to within 75 microns. They are available by subscription, with the M2 priced at $50,000 a year for a minimum term of three years.

BCN3D TECHNOLOGIES

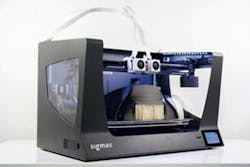

In September, BCN3D Technologies of Barcelona, Spain, unveiled the BCN3D Sigmax, a new fused-filament-fabrication desktop 3-D printer that begins shipping this month and joins the company's Sigma printer. It is available in the U.S. through distributors DesignBox3D and Matterhackers.

The printer has an independent dual-extruder system and a printing volume of 16.5 inches by 11.6 inches by 8.2 inches. Its new duplication mode enables users to print the same part with both print heads simultaneously, doubling the printing capacity. Mirror mode prints the part and its opposite at the same time.

The printer is available with a range of six hot ends (with nozzles from 0.3mm to 1mm) to make it more versatile. As a result, the Sigmax can print more-detailed models and fabricate sturdier parts in much less time than many other 3-D printers. It also can use abrasive materials.

The Sigmax also benefits from new software, the company said. BCN3D-Cura software provides an intuitive user interface and an optimized workflow to give customers increased reliability. The software integrates the printing profiles, ensuring the right set of parameters for any given combination of hot ends and materials.

The new printer costs about $5,300.

ULTIMAKER

A maker of open-source filament printers, Ultimaker recently made upgrades to its software.

This month, Ultimaker is releasing its Cura Connect, which will enable users to manage multiple print jobs across numerous printers from a single platform.

Earlier, the company made available workflow integration between third-party CAD applications for its Cura slicing software, which enables designers and engineers to customize their specific workflows, which the company sees as an advantage in printing parts for the automotive industry.

"Even customers that bought the very first Ultimaker 3 can benefit from the new software solutions provided in Ultimaker Cura, now, and in the future," Paul Heiden, Ultimaker senior VP of product development, said in a prepared statement.

"Ultimaker Cura opens up the possibility of third-party plugin development that ensures seamless workflow integration with industry-standard CAD software to make 3-D printing even more accessible," he said.

Phillip Britt, correspondent

For more information

BCN3D Technologies,Barcelona, Spain, 34-934-137-088, www.bcn3dtechnologies.com

Carbon Inc.,Redwood City, Calif., 650-285-6307, www.carbon3D.com

DesignBox3D,Sandusky, Ohio, 419-239-7065, www.designbox3d.com

Markforged Inc.,Cambridge, Mass., 617-666-1935, www.markforged.com

Matterhackers,Foothill Ranch, Calif., 949-613-5838, www.matterhackers.com

Photocentric Inc. USA,Phoenix, 623-581-3220, www.photocentricgroup.com

Ultimaker North America,Cambridge, Mass., 617-714-4748, www.ultimaker.com