Patent Report: Granulator takes on soft materials

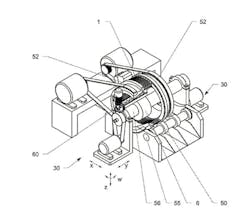

A new granulator proposed by shredder and pelletizer manufacturer BP Recycling Systems GmbH, Hofstetten, Switzerland, is designed to handle relatively soft materials, including some types of plastic waste. The new machine addresses issues that previously have limited throughput involving such materials, which tend to clump or become smeared. Large quantities can jam machines, or even start accidental fires, as they heat up due to friction.

According to a patent assigned to the company, a force-feed mechanism, such as a feed screw, introduces the bulk material to one or more pressure rollers in the compaction chamber of the dual-machine-body granulating apparatus. The combination of gravity and the rotation and centrifugal force of an annular die prevents material clumping.

In a configuration of the invention for plastics, material can be continuously fed into the compaction chamber. The configuration makes use of a direct-cooling apparatus. A quick turnaround of material prevents friction that could lead to excessive heat.

"It was surprisingly determined that waste material to be pelletized with the inventive apparatus requires less drying, wherein a relatively high moisture content can in fact be tolerated and even causes a cooling effect," the patent states.

The new machine can be used in conjunction with a cutting device or separating screens.

Patent 9,682,524; issued June 20

In other patent news:

Light curing. An inventor and a materials company, both based in Tokyo, have proposed a molding apparatus that uses light to melt thermoplastic resins in a mold.

A patent assigned to JSR Corp. and inventor Fumio Kurihara describes a machine that uses an electromagnetic wavelength of between 0.78 micron and 2 microns to melt resin inside two clear rubber mold halves. According to the patent, the process can handle large molds and complex geometries. The light moves sequentially from one section of unmelted resin to the next. In some variations of the invention, color-change sensors detect when resin has been melted; this information guides the light source's movement across the mold. One or both mold halves can be moveable.

A variety of resins, including ABS, PS, PA, PP and polyester-based materials, can be used in the process, either singularly or in combination; additives, such as fillers, fibers and modifiers also can be used. Because resins lose heat more slowly in rubber molds than when they're molded in metal molds, the plastics will exhibit greater crystallinity; for this reason, amorphous thermoplastics, which better maintain size and impact-resistance characteristics, are especially suited for the process.

Patent 9,682,497; issued June 20

Fixed platen. Fanuc Corp., Yamanashi, Japan, received a patent for a fixed platen for an injection molding machine that won't bend vertically and asymmetrically when mold clamping force is generated. Furthermore, the platen is prevented from falling due to nozzle-touch force. "Since the fixed platen is secured to the base frame by the first and second legs at spots near the substantially central portion and end portions, the degree of fall of the fixed platen caused by a nozzle-touch force can be made lower than in the case where the fixed platen is secured only at the central portion," the patent states.

Patent 9,701,052; issued July 11

Thermoforming. Essilor International, Charenton-le-Pont, France, was awarded a patent for a thermoforming machine for thin films used in optical and ophthalmic products such as glasses and contact lenses. The machine features a unit on the side of the machine that blows hot air parallel to the plastic film in the thermoforming chamber. The location of the blowing unit makes room for optimal placement of the film-sag measurement system outside and in front of the chamber opening, resulting in more precise measurements, the patent states. Additionally, the flow of hot air results in more uniform heating of the film and improved film quality.

Patent 9,694,534; issued July 4

Injection molding. A control technology devised by Nissei Plastic Industrial Co. Ltd., Nagano, Japan, takes into account changes that can occur to the parting opening during injection standby time — a period that's generally not monitored by other controls.

As part of the technology, a parting-opening detector resets if disturbances in pressure or temperature are detected from shot to shot. In preferred iterations of the technology, a control display shows data collected by a sensor that detects the positions of the moveable mold and the stationary mold during the period between the start of injection and the end of mold cooling. The method works best if completion of the preparation for injection includes either the conclusion of the nozzle-touch action or the stabilization of the mold temperature.

Patent 9,682,506; issued June 20

Foam molding. Greater control over the drive that operates the mold-clamping mechanism could lead to fewer molding defects, especially in foam molding applications, according to a patent issued to Toshiba Kikai Kabushiki Kaisha, Tokyo.

In its patent, the company states that problems can arise when a molding machine temporarily brings a moving mold into contact with a fixed mold and then slightly separates the two mold halves to allow foaming to occur. To achieve proper foaming, the machine must maintain optimal distance between the two halves; any variations on this distance can lead to defective parts.To address this problem, the company proposes a mold control that precisely rotates the drive motor to compensate for the initial contact of the two mold halves.

Patent 9,682,508; issued June 20

Gas venting. A Laval, Quebec, company that manufactures optical lenses has patented removable mold inserts capable of removing small gas pockets from mold cavities. According to DBM Reflex Enterprises Inc., these inserts can be used to meet the stringent tolerances of geometrically complex optical parts. Because the inserts are removable, they represent an improvement over gas-venting circuits, which can be difficult to maintain and clean.

Patent 9,676,130; issued June 13

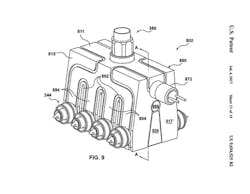

Edge gating. Mold-Masters Ltd., Georgetown, Ontario, received a patent for an edge-gated injection molding manifold assembly. The assembly is designed to solve the problems that can result from thermal expansion in linear arrays of mold gates, such as stress and damage to the nozzle tip, or defective parts. Additionally, the invention can simplify nozzle-tip replacement, according to the patent. The patent states that the upstream end of each nozzle seal slides relative to its respective melt outlet, while the downstream end of the nozzle seal is securely held relative to the mold gate. This allows the melt inlet of the nozzle seal to be misaligned with its melt outlet when cold without placing stress on the nozzle seal, according to the patent.

Patent 9,694,525; issued July 4

FRP manufacturing. Broetje Automation GmbH, Wiefelstede, Germany, has received a patent for a device and method for manufacturing components and preforms from fiber-reinforced plastic (FRP) more cost-effectively. The device allows for automated and continuous production of structural components with complex geometries, as well as curved components. The device shapes continuously supplied fibers using pressure rollers that form the fiber layers around a mold core. The device encompasses various modules, including an infrared heater, a device for application of the binder and a cutting unit.

Patent 9,707,726; issued July 18

Drying/degassing. Uhde Inventa-Fischer GmbH, Berlin, received a patent for a device that dries and degasses polyester resin pellets used in bottle preforms. Advantages of the device include energy savings due to reduced cooling requirements and better-quality pellets, according to the patent. The device features a temperature-control zone, a cooling zone and an inlet and outlet for the resin pellets.

Because a "partial flow of polyester pellets at high temperature is transported from the conditioning silo to the preform machines," cooling in the lower part of the conditioning silo can be omitted, saving energy. The patent also covers a method for molding parts from polyester resins.

Patent 9,707,702; issued July 18

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received a patent? Contact [email protected]