Press works in line with extruder to produce samples

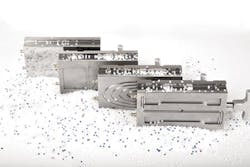

C.W. Brabender has introduced a new portable injection molding machine for testing compounds as they are being extruded. The SpeciMold machine produces an injection molded sample of a compound or other extrudate in a single step.

This compares to conventional methods of manufacturing the specimen, which is typically an off-line process that can be time-consuming. These methods expose the material to repeated thermal stress through additional melting that changes the material structure, said Paul Nardone, North American sales manager. SpeciMold manufactures a specimen that more accurately represents the properties and characteristics of the polymer being tested.

SpeciMold also can be used for material testing in R&D laboratories, and for recipe development in compounding lines. Additional applications include profile extrusion and film inspection, as well as use as a tool to determine melt viscosity by means of rheometric capillary die heads, according to the company. The SpeciMold machine can be used to process a wide variety of polymers and polymer blends without subjecting the material to a second melt history. The press can be set up to operate automatically.

Users can adjust the parameters of the machine to injection mold a sample for testing against a range of standards. It can be used to test for tensile stress, flexural properties, impact strength, temperature deflection under load, compressive properties, density and hardness.

GET A SAMPLE IN LINE

In a typical compounding line, SpeciMold is positioned between the extruder and the extruder die head. The company will not reveal details of how the machines are connected.

The SpeciMold machine features a chamber that is positioned beside the melt channel of the extruder. Filling the chamber with melt is the first step, occurring through a combination of either manual machine control, computerized pressure control and/or computerized time control.

An electrically driven piston creates injection pressure and pushes the material from the chamber into the mold. The piston has a maximum stroke of 135mm. The piston can inject a shot size of 27 cubic centimeters at injection speeds up to 50mm per second, Nardone said.

The material collection chamber has a volume of 33 cubic centimeters. The block and piston generate injection pressures up to 8,700 pounds per square inch (psi).

The molding side of the unit features a toggle clamping system that generates up to 25 tons of clamping force. C.W. Brabender manufactures and supplies the molds used with the system to generate the sample.

The software makes it easy for users to set injection molding parameters such as injection pressure, speed, volume, time and temperature. Process parameters specific to a material can be saved and retrieved whenever needed. The press provides a live data display for each process step. User-optimized control surface and process mapping of the software make it easy to set parameters to control the machine. Data such as the internal pressure curve in the injection mold can be saved to help operators to understand how to fill the mold effectively.

C.W. Brabender says SpeciMold has been tested with extruders having a 30mm-diameter screw, and it potentially can be used with larger machines.

Mikell Knights, senior staff reporter

Contact:C.W. Brabender Instruments Inc.,South Hackensack, N.J., 201-343-8425, www.cwbrabender.com