Materials Handling: Pneumatic systems gain upgrades

PNEUMATIC CONVEYING OPTIONS

Vacuum systems don't need pressure-rated components and are relatively easy to install and maintain, making them economical, even if they can be less efficient than positive-pressure systems, said Doug Brewster, conveying product manager at Conair.

Additionally, the systems can be cleaner because air leaks won't result in resin or dust blowing throughout the plant..

Processors can make the most of pneumatic resin conveying systems — both positive-pressure and vacuum-type — with new and upgraded components.

Kice Industries

Kice's new VJX airlock for pneumatic conveying systems hit the market in May.

The VJX airlock offers improved performance and reliability, according to the company. The patented bearing-and-seal cartridge eliminates the need for packing material around the shaft where it passes through the endplate. The bearing- and-seal cartridge not only outperforms traditional packing material, it also eliminates several previously required parts. The reduction in parts significantly reduces disassembly time, which leads to more uptime and lower operating costs, the company said.

A rotary airlock moves material, like resin pellets, continually while maintaining a constant air pressure between the inlet and outlet ports. Airlocks usually are found at the beginning of a positive-pressure conveying system or at the end of a vacuum conveying system.

The VJX airlock is interchangeable with existing Kice airlock models and is designed to comply with NFPA 69 standards for a passive isolation device. NFPA 69 outlines requirements for installing systems for the prevention and control of explosions in enclosures that contain flammable concentrations of gases, vapor, mist or dust. NFPA stands for National Fire Protection Association.

Kice also released a new, upgraded diverter valve, which allows a user to terminate a pneumatic conveying system at multiple destinations. Changing the setting on a diverter valve will divert the flow of material in different directions.

"A diverter valve is not new to Kice Industries," said Jeff Kice, technical sales. "We've manufactured diverter valves for quite some time, but this is an improvement to our existing diverter valve design."

The new design, which applies to valves ranging in diameter from 2 to 6 inches, offers more precise blade positioning, which reduces wear on the edge of the diverter blade, he said. It also offers improved drive-system guarding, which protects the system that remotely switches positions on the valve. The new diverter valve has more easily viewable position indicators so someone can look at the diverter and easily tell the direction in which resin is being directed, Kice said.

The new diverter valve is featured on Kice models 67Q2-2 through 67Q6-2 and models 68Q2 through 68Q6.

Conair

Conair has developed a way to maintain high throughputs and prevent resin damage by optimizing the conveying speed of its R-Pro variable-speed vacuum conveying system.

High-speed, or dilute-phase conveying, suspends pellets in high-velocity air to convey them to vacuum receivers on processing machines. The high speeds can cause soft pellets to smear against the sides of the tubing, resulting in streamers, angel hair and snake skins. Brittle resins can shatter, creating dust and fines. Very hard or abrasive materials can wear away the inside of conveying lines, eventually causing leaks. Traditionally, these problems have been solved by installing filters, angel-hair traps and special elbows to minimize wear.

Introduced in 2015, the R-Pro addressed those issues by conveying material at slower speeds, or what's known as "dense-phase" conveying, because the material moves in compact slugs.

Over the past year, Doug Brewster, Conair's conveying product manager, has been conducting additional research using the R-Pro system to convey materials at slightly higher speeds, but not so fast as to damage the resin. The high speeds approach the point at which material flow begins to shift from dense-phase to dilute-phase, he said.

"We've learned to control that transition very effectively — in fact, we can lock in on a sweet spot right on the edge in a kind of 'mixed-pulse phase,' " Brewster said. "This is what we call 'wave conveying' because the material sort of rolls like a wave on the ocean. The waves of material provide the kind of throughput rates that processors are accustomed to having and still avoid the problems caused by typical high-speed conveying systems running at dilute-phase speeds."

For highly abrasive glass- and mineral-filled resins, the slowest speeds are still the best, he said. However, the mid-range wave-conveying speeds of 1,200 to 2,000 feet per minute are good for resins like PET and acrylic, which are only mildly abrasive, and with low-bulk-density materials like PE sheet flake, he said. They are also effective for applications like rail-car unloading where more airflow might be desirable but truly high-speed operation is neither necessary nor desirable.

"It's really easy to raise or lower material speed and airflow," Brewster said.

The adjustments can be made with precision by using Conair's FLX128 Plus control system. The controller includes features developed specifically for the R-Pro system and allows users to fine-tune the system to accommodate the materials they are conveying. It can store recipes so the system can be quickly adjusted for different resins.

Maguire Products

Maguire Products' latest vacuum loading system is designed for conveying pellets and regrind from storage to one or multiple blenders. The LoPro vacuum loading system is simpler to operate than standard systems and consists of autonomously controlled receivers that are 80 percent shorter than conventional receivers.

"The key to the LoPro is it is taking vacuum loading and turning it on its side," said Frank Kavanagh, VP of sales. "What we mean by that is, it is a low-profile receiver. We have actually taken the receiver and turned it sideways and created a low-profile design."

The LoPro is easier to install where there is limited overhead clearance, Kavanagh said. In addition, it has a lower center of gravity, meaning it minimizes swaying on fast-cycling processing machines. Its receivers extend only 8 inches above the lid of a blender.

In addition, the receiver's discharge flap is three to six times wider than the flap on traditional upright receivers, making possible a dump time of only a second or two per cycle, depending on material flow properties. The wider discharge flap makes the receiver ideal for use with poor-flowing materials, such as PET flake or regrind.

Each receiver is self-controlled, with no central control required. Plug-and-play cabling and sequential linking of components ensure only one receiver operates at a time.

Maintenance has been simplified, with all operating components of the LoPro receiver being housed in a removable module that allows the receiver to remain in place. Modules are interchangeable, allowing production to continue even if service is needed.

The vacuum required to operate the unit can be supplied by a "mini-central" unit on a portable stand and is powered by a single-phase, 1.3-horsepower, brushless motor, which requires minimal maintenance. LoPro receivers also can be tied into a central vacuum conveying system, he said.

LoPro vacuum loaders have a conveying capacity of 1,300 pounds per hour over 12 feet and 1,000 pounds per hour over 20 feet. The company plans to offer larger LoPro receivers and vacuum pumps in the future.

Flexicon

Early this year, Flexicon introduced a new weigh hopper with a fill/pass valve for dilute-phase pneumatic conveying systems that handle resins and additives from pellets to fine powders.

Suspended from three small-scale load cells, the gain-in-weight hopper is more accurate than traditional loss-in-weight systems, the company said. The small-scale load cells accurately measure small quantities of material passing into a hopper and the unit transmits the weight gain information to a PLC. Once the batch weight has been reached, the valve redirects material away from the hopper. A controller then opens a slide-gate valve, which discharges the weighed batch.

The conical hopper is eccentric with a vertical sidewall that promotes complete discharge of weighed materials for batching accuracy. Stainless-steel construction makes the unit suitable for virtually any sanitary, corrosive or general plastics application.

Late last year Flexicon introduced Bulk-Out bulk-bag weigh-batch unloaders with seismic bracing.

The units provide added structural integrity and operator safety for installations in areas prone to earthquakes.

The BGC model discharger frame is equipped with a cantilevered I-beam and electric hoist and trolley for positioning of bulk bags without the use of a forklift. The bag lifting frame is equipped with patented Z-Clip bag strap holders that allow rapid insertion and removal of bag straps.

Four-sided cross-bracing strengthens the frame and reduces the risk of structural failure during an earthquake.

The unloader is mounted on load cells for loss-in-weight batching, and is offered with hopper transitions for discharging into pneumatic conveying lines, mechanical conveyors or downstream processes.

In addition, BFF model unloaders with seismic bracing are available for forklift loading of bags, and a BFH model works with a forklift or plant hoist to suspend the bag during discharge.

Novatec

Early this year, Novatec upgraded its SVP Silencer pumps with PumpSense predictive maintenance hardware and software at no additional cost.Novatec's Silencer pumps, without the predictive maintenance features, were introduced last summer. PumpSense technology was developed by Novatec in conjunction with its sister company, Prophecy Sensorlytics.

The air pumps provide powerful vacuums for pneumatic conveying equipment to transport free-flowing pellets, powders and regrind in single- and multi-receiver systems. The Silencer technology lowers the noise level, which improves worker safety. Silencer pumps operate at less than 80 decibels, which eliminates the necessity for a sound enclosure.

"Noise is becoming more and more of an issue in any plant working environment," said Jim Zinski, president and COO of Prophecy Sensorlytics and previously senior VP of product technology at Novatec. "It's a concern for plant and operator safety. Positive-displacement pumps are probably the most prevalent type of pump used, but they also are fairly noisy. This pump was designed specifically to keep the noise below 80 dBa without any additional sound attenuation."

Typically, if a plant manager wanted to minimize the noise from a vacuum pump, he or she would add a sound enclosure — essentially a large box with sound insulation — around the pump.

"That takes up additional floor space," Zinski said. "That also tends to be fairly costly — a $2,000 to $3,000 additional investment on a pump. This product was designed to try to leverage a smart component selection and package where the noise that it generates is simply lower than a conventional [positive displacement] type of blower, so it saves floor space versus other blowers, particularly when they have a sound enclosure."

The additional PumpSense technology provides information about pump performance, as well as preventive maintenance information designed to result in more efficient operation of the pump with less downtime for unplanned maintenance. PumpSense sensors can monitor conditions such as pump vibration, ambient temperature and vacuum levels at the pump inlet, all of which can help determine whether a pump is performing normally, and whether maintenance might soon be required. The monitoring can help identify whether filters need to be changed and the condition of oil and bearings.

"The purpose is to provide the customer with information they can use to proactively plan their maintenance schedule rather than performing maintenance on a routine schedule or not at all," Zinski said. "This product helps a customer plan their maintenance activities around the blower's conditions."

Sensor information is collected on the pump and sent to a data hub, which then connects to the customer's network and sends the information to Prophecy's cloud servers. Analytics are run in the cloud, and the information is presented to the customer via either a web browser or an app on a smart device.

The SVP Silencer pumps with PumpSense technology are available in 3-, 5- and 10-horsepower models that are capable of moving air volume at 55 cubic feet per minute (cfm), 100 cfm and 170 cfm, respectively.

Motan

Motan recently introduced two developments in the conveying sector.

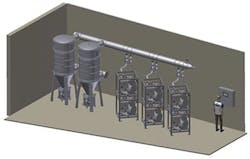

The company unveiled a central conveying system that provides continuous conveying activity for all connected equipment without the need for fixed vacuum lines. The central conveying system has only one central vacuum line. All material loaders, air pumps and filters are connected to the line.

"This is a different design than a typical pneumatic conveying system and different from what most people would be familiar with," said Scott Harris, VP of sales in the U.S. "This design has a large vacuum header that is constantly charged."

A typical central pneumatic conveying system has a vacuum pump and multiple receivers, but resin can be conveyed to only one receiver at a time. Motan's system allows users to convey material to as many as eight receivers at one time.

"This is specifically designed for high-throughput applications," Harris said.

A vacuum control automatically adjusts the air volume throughout the entire conveying system by regulating speed and switching blowers on and off as needed, according to the company. This provides the conveying system with the correct vacuum capacity it requires at any given time.

The system can convey more material since several hopper loaders can fill simultaneously, and the system reduces energy consumption by 30 percent to 50 percent compared to a standard central conveying system with line blowers, according to the company. It also offers simplified maintenance because fewer blowers and filters are installed.

Motan also introduced its MetroConnect U/C coupling system for pneumatic conveying systems.

Machine-dedicated conveying systems assign every processing machine its own conveying material feedline. Workers use a coupling station to connect conveying pipes to sources of resin. While coupling stations allow for quick material changes, the manual switching of uncoded couplings is a frequent source of error, which can have expensive consequences if the wrong material is conveyed to a machine.

Motan's new manually operated coupling station is available as either an uncoded version — MetroConnect U — or as a coded version — MetroConnect C — with maintenance-free radio-frequency identification (RFID) technology. The uncoded version can be upgraded to the coded version at any time.

Coded stations use RFID technology to prevent coupling errors. The technology also is beneficial if material tracking, validation or certification is required. RFID sensors and tags ensure material is transmitted to a processing machine only when the correct connections are made at the coupling station, the company said.

Up to eight blower lines, or vacuum systems, can be configured with the system. A maximum of 96 loaders and material sources, as well as up to 125 coupling points, can be connected to each blower line. If required, an extension of coupling points is possible.

RFID technology offers significant advantages compared to conventional technologies used with coupling stations, according to Motan. RFID transponder data can be read or written by a sensor without direct visual contact. Additionally, the technology reduces the risk of errors due to incorrect source and destination connections.

Plastrac Inc.

A new purge valve option from Plastrac makes it faster and easier to purge conveying lines.

The valve can be easily added to a vacuum conveying system that pulls material from a gaylord to feed a Plastrac hopper or loading system. It works with either regrind or granulated material and is available in 1.5- and 2-inch versions.

It was introduced at the K show but wasn't available for purchase until last month.

"The new purge valve will be a welcome addition for processors who lose valuable time having to suck 'slugs' out of the line when they clog loading hoses," said Eric Bullivant, Plastrac VP, referring to the material — virgin resin, regrind or an additive — that can build up where there are dips in the line.

It was developed in response to a customer request and is currently only for use with Plastrac systems, but there are plans in place to make it a retrofit for other systems as well.

Dri-Air Industries

Dri-Air in June announced it upgraded its Hopper Bank with an integrated central air conveying system designed for operators of small injection molding machines or extruders. The new design now includes an enhanced touch-screen controller with additional controls. The new color touch screen provides fast and easy setups, company President Charlie Sears said.

"We recently added our touch-screen control, which allows easier and more complete control of the system," Sears said.

The new system is designed for molders running multiple resins.

"This is made specifically for small presses for people who use 1.5-inch tubing instead of the larger 2- or 3-inch," he said. "We took our Hopper Bank and incorporated a closed-loop loading system the customer could easily install in his plant."

Purchasers of the system can run their own conveyance piping or tubing from the unit over to their presses.

The unit connects one dryer to multiple hoppers for a centralized drying system. Different materials can be dried in each hopper, as each has its own booster heater for temperature control. Quick-change manifolds allow operators to switch from one hopper to another or to connect multiple machines to one drying hopper.

A vacuum pump, vacuum receivers and a controller are built into the system, Sears said.

"All you have to add is the tubing to the receiver and a T-valve," Sears said.

Systems are available for up to 10 machines. Hopper Banks are available with hopper capacities from 5 to 600 pounds and with two to 12 hoppers.

Bruce Geiselman, senior staff reporter

For more information

Conair Group,Cranberry Township, Pa., 724-584-5500, www.conairgroup.com

Dri-Air Industries Inc.,East Windsor, Conn., 860-627-5110, www.dri-air.com

Flexicon Corp.,Bethlehem, Pa., 610-814-2400, www.flexicon.com

Kice Industries Inc.,Wichita, Kan., 316-744-7151, www.kice.com

Maguire Products Inc.,Aston, Pa., 610-459-4300, www.maguire.com

Motan Inc.,Plainwell, Mich., 269-685-1050, www.motan.com

Novatec Inc.,Baltimore, 410-789-4811, www.novatec.com

Plastrac Inc.,Edgemont, Pa., 610-356-3000, www.plastrac.com

Prophecy Sensorlytics,Baltimore, 443-457-1165, www.prophecysensorlytics.com

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.