Special Report: Suppliers unveil latest process monitoring systems

Three global suppliers of process monitoring systems recently rolled out or are working on updated hardware, software and components that better capture and compare injection molding machine or mold data.

One of these advancements is a new process monitoring system that helps the injection molding machine operator return an out-of-specification process to optimal processing conditions. RJG Inc. is a developer of monitoring and control technology, advanced molding techniques, training and equipment. Its most recent development is the CoPilot.

"The CoPilot is a new, interactive process monitoring system that observes actual machine settings and offers step-by-step instructions to bring a process back within parameters," said Bob Reese, an RJG senior consultant. The software is being beta tested at 10 sites.

What makes the CoPilot unique is that when process variables move outside of limits set by the molder, the monitoring system can determine what the most important out-of-specification variable is. The system prioritizes the variables, then provides a sequence of operational steps that the operator can follow to correct the issue, the company said.

RJG has incorporated the expertise it has gained in scientific molding and injection molding into the system, which allows the CoPilot to understand relationships between process variables. A single critical variable out of compliance can send multiple variables out of limit.

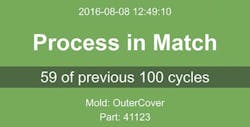

"The knowledge we put into the system takes these process relationships into consideration and provides a sequence of operational changes," Reese said.RJG calls the CoPilot a process match assistant because it is designed to ensure that the process matches the documented setup created by the molder. Through a touchscreen interface, the user selects the optimal, upper and low values for each variable. The CoPilot not only captures the number of changes that occur on each job, it helps the molder determine if the changes made were the right changes.

Users set up CoPilot by running their process until it is stable and good parts are made. Then they click a "populate" button on the set-up screen that imports all values into an "Optimal Value" column. By doing this, the user creates a set of template values.

If a parameter exceeds a control limit, the molder can tap the touchscreen, where a process change log entry window appears. Users enter their names in the log entry window and can then choose to follow instructions provided by the system of make their own adjustments.

RJG is designing a report generator for the CoPilot that can be modified for each user. "A machine operator can print out a summary of problems encountered during a shift and what was done to fix the problem, while a quality manager can view downtime occurrences or find out how many parts ran out of match," Reese said. The system records if operators made changes in accordance with software suggestions.

"Having the unit properly predict what needs to be done to put the process back is our main focus in developing the system," Reese said. Using the CoPilot, a molder can identify process changes that occur often during production of a part. The system pinpoints the source of trouble, allowing the molder to focus on steps to minimize the issue.

In addition to helping put the process back, the CoPilot documents that the process has remained within established limits, Reese said.

"This allows molders to have confidence that they're only shipping good quality parts to their customers," he said.

By developing the CoPilot system, RJG hopes to provide injection molders with real-time notifications when their process strays, understand why their process has changed and get the process back on track regardless of skill level. RJG officials believe this will help improve part quality and bridge the skills gap. The CoPilot will be released later this year.

KISTLER UPDATES SYSTEM

Kistler Instrument has upgraded its ComoNeo system for mold cavity-pressure-based process monitoring and control. The 2.0 version offers two approaches to good part/bad part determination based on a machine operator's expertise level — EO Assistant and Stasa QC software.

ComoNeo 2.0 analyzes sections of a cavity-pressure curve to determine whether a user-selected value has been reached. This determination forms the basis as to whether the part will be good or bad.

For new users with minimal experience working with cavity-pressure analysis, Kistler offers EO Assistant, a software program that automatically defines, generates and precisely plots evaluation criteria to monitor part quality. The program overlays graphs showing actual process data, with boxes that indicate the parameters that will result in good parts. Part quality can be determined before the mold is opened using the program, which evaluates the reference point to a specified tolerance. From looking at the graphs prepared by the program, users can determine whether the part has been molded properly or has been affected by conditions such as a short shot or sink marks.

EO Assistant, which was available in the original version of ComoNeo, has improved accuracy so that good parts aren't incorrectly classified and thrown away, said Daniel Fick, business development manager.

For users with expert-level knowledge of cavity pressure, Kistler has developed its Stasa QC software, which offers a greater level of detail and customization than EO Assistant. After the user performs molding trials while using Stasa QC, the program can create predictive models showing ideal processing parameters.

"The software uses a mathematical algorithm to calculate a link between the cavity pressure curve and the quality feature, which can be a dimension on the part, the weight of the part, other feature or process variable. The process or production engineer saves the parameters onto a USB flash drive, then uploads the information to the injection press, where parts are made based on the uploaded machine settings," Fick said.

Using the data, Stasa QC software creates a predictive model linked to the pressure and temperature measurements taken from the mold. The software produces a model of part quality that can be predicted on the basis of process measurements.

This approach creates optimal upper and lower limits and a molding profile for a part.

Kistler also developed a new module that shortens the time to good production when a mold is transferred from one machine to another. The Restart Assistant saves a reference cycle reflecting ideal process settings with a given mold to the ComoNeo 2.0. When the mold is transferred to another injection machine, the data are retrieved and an analysis is made between the reference curve and actual measurements attained during processing.

ComoNeo 2.0 analyzes the differences between the two curves, then suggests changes to the molding parameters to align current molding conditions to the reference, Fick said.

In addition, Kistler introduced a new control option for ComoNeo 2.0 that is designed to achieve more balanced filling. The MultiFlow Control adjusts the temperature of each hot-runner nozzle in a multicavity tool to balance material flow into each cavity.

Kistler said that it also recently integrated ComoNeo with OPC-UA protocols, allowing it to communicate directly with a wide range of hot-runner controls and injection molding machines.

PRIAMUS UNVEILS NEW DEVELOPMENTS

Priamus System Technologies announced several developments at the K show, including a mobile version of its FillControl Monitor module for process monitoring, a new flat-panel computer for use with its line of FillControl products, an updated system that automates valve-gate control for liquid silicone rubber (LSR) and the incorporation of a communication protocol for better connectivity to devices.

The portable version of FillControl Monitor has all the features and functionality of the standard version and links to a molding machine in the same way, said Marcel Fenner, president and technical manager.

"A molder visiting the mold maker can link directly to their mold and record cavity temperature, cavity pressure and other data points," Fenner said. The user can take the process data back to the molding plant and upload it to the press as a reference setting for the mold when it arrives and is mounted. The user can compare current settings from the injection machine to the reference curve stored in the portable unit and make adjustments so that the tool runs according to the specifications established by the mold maker. Data from the mobile FillControl Monitor can be imported into the standard FillControl Monitor if needed, Fenner said.

Priamus also developed a new flat-panel computer called BlueLine Core type 8280C, designed for use with its line of FillControl software. The panel has a 15-inch touch screen and incorporates a data-storage device. The computer has three standard Ethernet interfaces, Fenner said. Compared to the dual-core design of the previous BlueLine Core type 8280B, the quad-core BlueLine Core type 8280C has increased processing power for better performance.

Priamus also introduced its new FillControl V module, designed to balance hot- or cold-runner valve-gated molds using mold-cavity temperature curves to control the valve pins.

The system automatically detects the melt front and calculates an optimized setting of the pin stroke for each cavity. In the past, FillControl V would delay the opening of the pins as a means of control. Now the system controls the action of each servo-actuated valve pin directly, Fenner said. The ability to position and control the pins in the corresponding valve gates directly, as a function of melt flow, allows multicavity molds to be balanced without having to change the nozzle temperatures of the hot runner, Fenner said.

FillControl V is suited for use with LSR as well as thermoplastics, the company said.

Mikell Knights, senior staff reporter

For more information

Kistler Instrument Corp.,Novi, Mich., 248-668-6900, www.kistler.com

Priamus System Technologies,Brunswick, Ohio, 877-774-2687, www.priamus.com

RJG Inc.,Traverse City, Mich., 231-947-3111, www.rjginc.com