IML now targets many-cavity, thin-wall molds

Suppliers of molds, automation and injection molding machines introduced advances in decorating technologies, including new in-mold labeling (IML) approaches for thin-wall and high-cavitation applications.

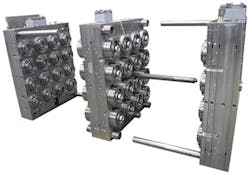

STACKTECK DEVELOPS MOLD TO HANDLE HIGH-CAVITATION IML

Late last year, injection mold maker StackTeck Systems sold a high-cavitation tool specially designed to produce single-serving cups with a wraparound label, said Jordan Robertson, GM of business development and marketing.

"Demand for high-cavitation tooling with IML is relatively new. This two-level stack tool, with 32 cavities, represents emerging new applications. We have built many higher-cavitation tools for cup production, but [do so] less often for use with IML," Robertson said.

The tool is designed so that each set of 16 cores — one for each mold face — is positioned on the center section of the stack tool. Each mold half has 16 cavities that are joined with the cores in the center section. This approach, along with the use of a special hot-runner manifold and related technologies developed by the company, allows the mold maker to position the gate on the outside of the molded part, rather than on the inside, where it would create a gate vestige inside the part.

The mold features two hot runners installed in each mold half. To deliver material to the cavities on the moving mold half, the mold has a 2-inch-diameter sprue bar that extends through the stationary mold to the center of the core plate. The melt channel directs material flow from the sprue bar at the center of the core plate into a small manifold.

The small manifold then directs the melt down the center line of the core plate assembly to a T-section that splits the material flow to both ends of the bottom of the center mold section. Melt travels from the ends of the center section and through a nozzle crossover device and into the cavity sides on the platens. There, a second hot-runner system delivers the material to each cavity. A valveless melt-transfer system depressurizes the melt each cycle when the mold is open and the cavity section is disconnected from the center section of the stack mold, Robertson said.

StackTeck has built hot-runner, manifold and related melt-flow components for its stack molds for 35 years, and is increasingly enhancing them for IML. Robertson said the technologies allow for gating inside or outside of a part molded on a stack mold. The company has built more than 50 IML stack molds; more than half run with 16-plus labels per cycle.

BECK AUTOMATION CREATES IML SYSTEM FOR LONG CYLINDRICAL PARTS

IML automation from Beck Automation was a critical component in a demonstration cell at the K show producing long, thin-walled, cylindrical packaging in a high-speed, multicavity operation, company President Nicolas Beck said.

Beck Automation designed an IML system, complete with robot and related equipment, that places labels into a 16-cavity mold for cylindrical cartridges used to hold sealants such as caulk or silicone, he said. Approximately 10 inches long, each part had a shot weight of 46 grams and a wall thickness of 1.2mm. For the industry, it is among the first examples of decorating cartridges with this extreme length-to-diameter ratio using IML technology.

Designed for high-speed packaging applications, an e-speed 500 from Engel Austria, Schwertberg, combined with IML technology from Beck Automation and a mold designed by Otto Hofstetter AG, Uznach, Switzerland, to produce the HDPE parts in cycle times of 13 seconds. The molding machine achieved very fast cycle times while handling the relatively high total shot weight of 800 grams.

The placement of a wraparound label into each of 16 mold cavities required highly precise movements of the machine platen and automation. The positioning between the steel dimension of the mold cavity and the mandrel of the IML system that places the labels is critical to precise and repeatable placement. The gap between the mold and IML mandrel during label placement is no greater than 0.3mm.

High-cavitation IML applications are increasing. "We have projects or applications today requiring 32 cavities, with discussions up to 48 cavities. Yet, this is for parts with a more forgiving geometry," he said. For the demonstration, Beck Automation developed a new label magazine that reduces the manual labor involved with restocking the label magazine. "Because it takes time to refill 32 magazines with labels, we developed this new design concept that reloads the labels without a stop in production," Beck said.

Traditionally, sealant cartridges are molded, then decorated downstream from the press. Though offset, flexographic and digital printing are less expensive than IML, the printing techniques can't match the quality of IML. Use of IML gives the molder a chance to consolidate operations while gaining a value-added function, Beck said.

Typical molding systems producing sealant cartridges use eight- or 16-cavity molds. "We needed to demonstrate that high-cavitation IML molding is a viable [alternative] to downstream printing," he said. The company has sold a similar 16-cavity IML system for cartridges to a molder based in Turkey.

WITTMANN BATTENFELD UNVEILS IML AUTOMATION SYSTEM

At the K show, Wittmann Battenfeld, a maker of injection presses, automation and materials-handling equipment, presented its new W837 IML system built around its W837 side-entry robot. The system is the company's latest development for high-speed, compact IML, and will be continuously optimized with regards to footprint, production flexibility and energy use, the company said.

The system at the K show produced PP lids in an eight-cavity mold, with a cycle time of 4.7 seconds, said Andreas Klackl, division manager of robots and automation at Wittmann Kunststoffgeräte GmbH in Vienna.

The W837 IML system, comprising the robot for label insertion and part takeout, conveying system and enclosure, also incorporated a camera for part inspection. A synchronized conveyor belt separated good parts from bad parts.

Servo drives govern the movements of the critical components in the IML system. The servo motors let the user optimize dynamic movements, while an integrated vacuum pump minimizes the system's compressed air requirements, according to the company.

Users can produce lids that are of different dimensions, through simple adjustments, according to Wittmann Battenfeld. The machine and automation were designed to make the work cell more compact, while a highly dynamic horizontal axis allows for fast insertion and removal movements.

Mikell Knights, senior staff reporter

For more information

Beck Automation LLC,St. Louis, 314-576-9736, www.beckautomation.com

StackTeck Systems Ltd.,Brampton, Ontario,416-749-1698, www.stackteck.com

Wittmann Battenfeld Inc.,Torrington, Conn., 860-496-9603, www.wittmann-group.com