Mitsui Seiki machining center is safe and accurate

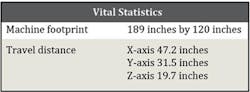

PJ812 Precision Profile Center Mitsui Seiki's new three-axis CNC vertical machining center is designed for high-precision contour machining and boring of molds and dies with critical tolerances. It can handle loads as heavy as 3,300 pounds on its 48-inch-by-32-inch work surface and offers two spindle choices: a 10,000 rpm, 50-taper version with a motor that provides 20 horsepower (hp) of constant power or up to 40 hp for 30 minutes; or a 30,000 rpm, 40-taper version that provides 20 hp of constant power or 24 hp for up to 30 minutes.

What's new? The machining center, which was introduced in January.

Benefits Precision, safety and efficiency. The PJ812 offers positioning accuracy and repeatability of within 1 micron, and is fully enclosed for complete containment of chips and coolant. The model features a thermal compensation system that reduces the effects of temperature-generated displacement by about 60 percent, as well as z-axis thermal growth and deflection by 30 percent. It is also equipped with an energy-saving circuit that can reduce energy consumption by 90 percent and compressed air consumption by 40 percent.

Mitsui Seiki USA Inc., Franklin Lakes, N.J., 201-337-1300, www.mitsuiseiki.com