Special Report: Drying resins requires taking various precautions

Some resins are more difficult than others to dry, and different resins require different precautions, said Mark Haynie, VP of Novatec's dryer technology.

"If all I had to do was dry polycarbonate and ABS, I would be the happiest person in the world," Haynie said, citing them as among the easiest resins to process.

However, other resins require precise drying conditions.

HIGH-TEMPERATURE RESINS

When drying high-temperature resins such as PC, PET, PEEK and some others, processors must ensure the air temperature entering the desiccant dryer from the drying hopper isn't too high. Desiccant dryers constitute the majority of dryers in use.

"What you have to ensure with high-temperature resins in particular is that the process air comes back at a temperature of definitely less than 150 degrees Fahrenheit, and we like to see around 130 degrees Fahrenheit and no more coming back to the desiccant," Haynie said.

If the temperature of the air entering the dryer is too high, the desiccant won't be effective in removing moisture. When drying PET and some other high-temperature resins that are heated to more than 220 degrees Fahrenheit, desiccant dryers often need to get dew points down to minus 40 degrees Fahrenheit, and moisture in the resin down to 50 parts per million (ppm).

High-temperature resins sometimes are heated to more than 220 degrees Fahrenheit in drying hoppers. To reduce the temperature of the air to less than 150 degrees Fahrenheit before it is conveyed into the dryer, a cooling coil must be added between the hopper and dryer. Typically, the cooling coil — also called an after cooler — is installed following a process filter, which removes dust and plastic particles from the air.

Equipment manufacturers usually include after coolers with all desiccant dryers regardless of whether a processor plans to use it for drying high-temperature resins. That's because even if a client doesn't plan to use the dryer for high-temperature resins initially, it could be used for high-temperature resins in the future.

"We, as a company, always include the cooling coil," Haynie said, adding that some manufacturers offer the cooling coil as an option.

LOW-TEMPERATURE RESINS

Low-temperature resins are more difficult to dry than high-temperature resins because, if the temperature of the air re-entering the hopper from the dryer is too high, it can not only damage the material but damage or destroy the hopper itself.

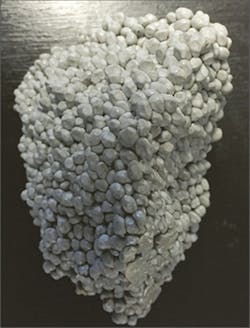

When air re-entering a hopper dryer gets too hot, it can cause pellets in the hopper to fuse into a mass. With some resins — including PETG, copolyesters and polylactic acid — drying temperatures need to remain below 160 degrees Fahrenheit. Temperatures inside the dryer can rise above that level due to heat given off by blowers and the exothermic reaction that occurs when the desiccant absorbs moisture.

"The biggest thing with low-temperature resins is, if you put too high of a temperature into the drying hopper, you form a 'Texas pellet,'" Haynie said. "You need a jackhammer to actually get it apart. You're going to have a machine that is down for a long, long period of time."

Sometimes the material can't be chiseled out of the drying hoppers and the equipment needs to be replaced, Haynie said.

To avoid that situation, equipment manufacturers add a pre-cooler that chills the air after the drying process, before the air re-enters the heater on the drying hopper. A process heater can reheat the chilled air to the 130 degrees Fahrenheit to 150 degrees Fahrenheit required to dry the low-temperature resin properly without overheating it.

Low-temperature resins require longer drying times than high-temperature resins because the process does not put a lot of heat into the resin.

NOTORIOUSLY DIFFICULT RESINS

"There are resins that are notorious for being problematic," Haynie said. "Probably the No. 1 resin for being problematic is the No. 1 used resin: nylon."

The reason nylon is so difficult to dry is because it can hold much more water than other resins. For example, while PC is totally saturated at 4,000 ppm of water, nylon can hold 20,000 to 25,000 ppm.

Nylon may come in sealed gaylord containers from a vendor at a moisture level appropriate for processing, but as soon as the container is opened in a humid environment, it begins sucking moisture out of the ambient air. In a matter of a few hours, there may be enough moisture in the nylon to damage the quality of the end product.

PET processing also presents unique challenges associated with regrinding or reprocessing. When processors use amorphous PET regrind in quantities greater than 15 percent to 20 percent, a crystallizer must be used. The crystallizer adds agitator arms to a drying hopper to convert PET from an amorphous state back to a semi-crystalline state. The drying needs to be done at high temperatures of more than 300 degrees Fahrenheit and with low-dew-point air of minus 40 degrees to minus 60 degrees Fahrenheit to achieve the moisture content required for proper processing. After drying, the resin must be handled properly to ensure no moisture is reintroduced.

Bruce Geiselman, correspondent

Contact:

Novatec Inc., 410-789-4811, www.novatec.com

About the Author

Bruce Geiselman

Senior Staff Reporter Bruce Geiselman covers extrusion, blow molding, additive manufacturing, automation and end markets including automotive and packaging. He also writes features, including In Other Words and Problem Solved, for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. He has extensive experience in daily and magazine journalism.