Alliance seeks to reduce costs of mold insert process

Use of additive manufacturing (AM) to produce metal mold inserts offers great promise, but has been slow to take off because it's expensive.

An alliance between two key players aims to reduce costs through more efficient use of equipment. Improved component quality is also a goal.

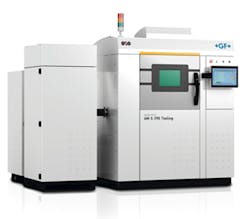

GF Machining Solutions Management SA, Lausanne, Switzerland, teamed with EOS GmbH Electro Optical Systems, Krailling, Germany, to develop the AgieCharmilles AM S 290 Tooling machine, which was exhibited at the K show. GF Machining Solutions' AgieCharmilles product line is one of the leading brands in machine tools used in mold making, while EOS is a leader in direct-metal-laser sintering (DMLS), an AM process.

One benefit of AM is the ability to make internal, curving channels in a mold that can deliver cooling closest to the points where it is most needed, Bernd Wiedmann, area sales manager for EOS, said during the K show.

Stefan Dahl, head of new technologies for GF Machining Solutions, said: "Together, GF Machining Solutions and EOS envision the integration of AM into the manufacturing process chain, and are moving forward with a clear vision and a solution-oriented approach. … With EOS as our strategic partner, AM technology becomes part of our portfolio to resolve customers' manufacturing challenges."

The AM S 290 Tooling machine incorporates the EOS M 290 metal-laser-sintering system with controls and software that allow easy and fast integration with machine tools and measuring devices, the companies said.

The machine also incorporates mechanical systems commonly used in the machine tool industry, such as reference chucks and palletizing, that allow transfer of work from one machine to another while maintaining the position of geometric features.

The machine includes an integrated MacroMagnum chuck, from GF Machining Solutions' System 3R (S3R) brand.

"The chuck, combined with reference-point calibration software, allows better integration before and after the building process," said Doḡan Basic, product marketing manager for AM at GF Machining Solutions. "The first big advantage is when you fix the conventionally manufactured preforms on the build plate. Then you fix the plate on a System 3R MacroMagnum chuck outside of the machine and, thanks to a coordinate measuring machine, you can define the coordinates of the preforms. When you put the building platform back on the MacroMagnum chuck inside the machine, the reference calibration software ensures extreme precision when you print directly on top of the preforms."

It's also possible to print on a single preform that is placed on an S3R pallet that is fixed on the chuck. That's important because the parts must be heat-treated following the AM build. "The pallet must be removed prior to heat treatment but, depending on the required tolerance, replacing the part on the pallet is not critical," said Basic. The pallet with the insert can then be placed into a machine tool.

"Another added value for the integration is when you need to print directly on the build platform," Basic said. "Having a build platform with a pallet system helps to fix it in an EDM machine equipped with an S3R pallet system. You can then more efficiently separate your parts from the build platform."

When plates need to be refurbished before the next job, they can be placed in a machine tool equipped with the same chuck.

More work is being done to improve the technology.

"The chuck is not the perfect solution for complete integration, but it is already adding value in many cases," Basic said. "We are currently working with EOS on solutions to further improve physical integration and to advance software combinations."

The companies declined to divulge any data on the number of systems sold to date.

Doug Smock, senior correspondent

Contact:

EOS of North America Inc., 248-306-0143, www.eos.info

GF Machining Solutions LLC,847-913-5300, www.gfms.com