Companies feature PPT extrusion innovations

Makers of technologies for pipe, profile and tubing extrusion showcased their innovations during the triennial K show in Düsseldorf, Germany.

Battenfeld-Cincinnati

Battenfeld-Cincinnati GmbH showcased several innovations in its booth, including the conEX NG — the NG stands for "Next Generation" — a series of conical twin-screw extruders with three models. The goal was to introduce a line that is flexible, yet allows clients to make products at low cost.

The ConEX NG 65 was on display at the booth. "You can use it as a stand-alone machine; there are also a lot of coextrusion options," said Judith Lebic, head of marketing for Battenfeld-Cincinnati, during an interview with Plastics Machinery Magazine during the K show.

Battenfeld-Cincinnati wanted to launch a global machine with a robust, mechanically flexible drive train and improved screw-tempering system, according to the Bad Oeynhausen, Germany, company. The screw core design allows for easy adaptation to different temperature control systems, making the machine suited to different end markets and products. The series is engineered to handle continuously increasing tool back pressures and has the ability to operate under a permanent process pressure of up to 7,542 pounds per square inch. Higher tool back pressures are required for end products that have more complex geometries and thinner wall thicknesses.

The machines have been completely redesigned in terms of process technology. There is a longer pre-heating zone and the screw design has been optimized, which provides higher outputs, Lebic said. The geometry of the screw design allows for a balance between mechanical energy input over shear and thermal energy input, increasing the number of PVC-based materials that can be processed with just one screw configuration.

The company has a U.S. operation: Battenfeld-Cincinnati USA, McPherson, Kan.

Drossbach Maschinenbau

Drossbach Maschinenbau GmbH, Rain am Lech, Germany, displayed its new four-layer die head for corrugated pipe production used for wastewater, rainwater and drainage applications.

Officials said that the multilayer structure allows for improved mechanical properties, which are necessary for pipes that are buried in the ground.

The die is designed to produce pipes made from PE or PP, with the ability to use recycled plastic in the middle layers. The maximum output is about 2,094 pounds per hour, where the maximum PE/PP output for the outer surface layer is about 265 pounds per hour, and the maximum PE/PP output of the inner surface layer is about 198 pounds per hour.

Greiner Extrusion

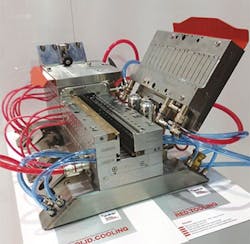

Greiner Extrusion GmbH, Nussbach, Austria, had on display its Solid.Cooling calibration technology, which is used downstream in profile extrusion for holding the shape while the profile is cooled. This system employs a special, high-strength, beryllium-free copper alloy that has better thermal conductivity than steel.

According to the company, the design and engineering are the differentiators. Designated calibrator sections do not have the small, cross-section cooling channels that are typically used; therefore, these sections are not at risk for contamination or blockages.

Werner Huber, Greiner's VP of sales, said that Solid.Cooling allows for more net production time because the technology prevents small cooling holes from clogging — a mechanical risk that can inadvertently change the profile geometry, taking it out of tolerance or impacting other specifications.

Cleaning and maintenance are significantly easier. The system is much less prone to contamination in the water circuit, or fluctuations in water pressure or temperature. Solid.Cooling is for use exclusively with Greiner's systems, including its Red.Tooling series.

Greiner is represented in the U.S. by Greiner Extrusion US Inc., Meadville, Pa.

Hans Weber Maschinenfabrik

Hans Weber Maschinenfabrik GmbH, Kronach, Germany, focused on the overall efficiency of the extrusion line at the K show, unveiling a new generation of extruder control.

"Extrusion, with all its varied possibilities, is becoming ever-more complex," said managing director Michael Weber. "That is why industrial companies need a reliable consultant, project manager and manufacturer."

The company said that as extrusion becomes more complex, the controller must be made simpler, which is essentially a prerequisite for efficient production. At the K show in 2013, the company introduced its centralized control system known as WPS3, which is touted as the "cockpit" controller. When it comes to line networking and optimizing conditions, the controller allows the user to monitor energy usage; preset the water temperature for the cooling tank; and perform preliminary calculations and tweaking of line variables as needed, including tensions in the pipe.

At this year's show, Weber introduced the WPS4, featuring voice control and an improved touch screen, which visitors were able to test in the booth.

Weber is represented in North America by Bundelplast S.A. de C.V., Tlalnepantla, Mexico.

Angie DeRosa, managing editor

Contact:

Battenfeld-Cincinnati USA, 620-241-6843, www.battenfeld-cincinnati.com

Drossbach Maschinenbau GmbH, 49-9090-702-0, www.drossbach.de

Greiner Extrusion US Inc., 814-333-2060, www.greiner-extrusion.com

Hans Weber Maschinenfabrik GmbH, 49-9261-409-409, www.extrudertechnologie.de

Bundelplast S.A. de C.V., 52-55-5361-5277, www.bundelplast.com