Compounders of recycled plastics are looking to extruder makers for innovations that will help their products compete with low-priced virgin resin.

KraussMaffei Berstorff GmbH

KraussMaffei Berstorff GmbH, Hanover, Germany, offers its EdelweissCompounding line of extruders for recycling and compounding. The line includes co-rotating twin-screw extrusion technology for melting and alloying polymers, and filling, reinforcing and producing masterbatches. It has twin-screw and single-screw extruders for post-consumer and post-industrial waste. It also offers single-screw extruders for repelletizing.

The company said the advantages of twin-screw over single-screw extrusion include optimized degassing, melt homogeneity and better filtration.

In the U.S. market, KraussMaffei is finding success from the "cascade approach" using two twin-screw extruders or one single-screw extruder and one twin-screw extruder. The first extruder melts and degasses the recycled plastic, and then the material gets filtered through a continuous filter. Next, the clean, homogenous melt is transferred through a melt pump into the second twin-screw extruder, where the focus is on compounding. The twin-twin cascade allows processing of about 7,700 pounds per hour in the recycling stage and more than 11,000 pounds per hour in the compounding stage.

"Splitting the task up allows us to generate the most energy-efficient approach and to optimize both extruders in terms of their dedicated recycling and compounding applications," said Carl Poepel, product and sales manager, twin-screw extruders, for KraussMaffei. "This also results in the highest flexibility regarding the compounding task because the cleaned, homogenized melt can be compounded with fillers — fibers of specific additive packages, according to the customers' preference. Using a [twin-screw] makes the system 'polymer independent' because an adaptation in the field of the screw design and barrel layout allows [the running of] nearly every polymer with the same base machine setup."

Poepel said degassing and melt filtration are important in recycling, so material must be dried in the extruder before mixing in additives, to allow for maximum performance.

American Starlinger-Sahm Inc.

American Starlinger-Sahm Inc. is a Fountain Inn, S.C.-based company that specializes in machinery for recycling. To provide cost efficiency, Starlinger's RecoSTAR Dynamic and RecoSTAR Universal machines allow customers to reduce material size, filter the melt, devolatilize, compound and pelletize in a single process, said Alan DiUmberto, sales manager, recycling division for the company.

The two machine lines have been designed to meet different needs. The RecoSTAR Dynamic features an automatic temperature control that allows for the processing of input materials with different moisture levels — a technology that allows it to handle hygroscopic, wet and foamed materials.

The RecoSTAR Universal, on the other hand, is designed for rigid, flexible and hard-to-grind materials. The system includes an Active shredder and load-controlled dosing screw for stable feeding, even when bulk densities vary.

In combination with any of its RecoSTAR extruders, Starlinger markets an approach known as C-Vac, which deploys a special, second single- screw extruder called a C-Vac for compounding. In this approach, the first extruder is used as a pump to compress and melt the polymer, which then enters a melt filter, where many volatiles are removed. To eliminate the remaining volatiles, the polymer then enters the C-Vac, which is designed especially for degassing. The C-Vac optimizes the surface area of the polymer, exposing a maximum amount of it to vacuum, so that volatiles can be removed as gas.

The extruder's frequency-controlled motor also facilitates compounding, with glass fiber added after melt filtration for minimal breakage of the fiber.

"This ensures that additives are not removed by a filter right after being put in the extruder," DiUmberto said.

The C-Vac approach is geared toward heavily contaminated and printed material, offering strong degassing efficiency and increased output.

"Recycling has to become a part of the business model in order for it to be relevant," Di-Umberto said. "Other commodities such as steel, paper and aluminum are recycled and become part of the business model in making new products. The technology has been developed to increase recycled content in new products, but unless it is part of the model, it will not be sustained."

American Leistritz Extrusion

Co-rotating, intermeshing twin-screw extruders are often used for processing post-industrial resin (PIR). They are not used as often for post-consumer resin (PCR) applications, "although this is changing," said Charlie Martin, president and GM for Somerville, N.J.-based American Leistritz Extrusion.

Because the extruders are used for compounding fillers and additives into a resin, as well as for the removal of moisture and other undesirable volatiles from the melt stream, "there is a trend to integrate compounding and devolatilization functionalities into reclaim extrusion systems for both PIR and PCR applications," Martin said. "Understanding the feedstock materials, final product property requirements, careful staging of unit operations, integration of the correct equipment and system controls must all be addressed for a successful installation."

Martin said technical challenges often relate to feeding regrind materials, filtration and devolatilizing feedstocks with residual moisture to accommodate compounding reclaimed materials with a twin-screw extruder in a one-step operation.

Leistritz makes High Speed, Energy Input (HSEI) twin-screw extruders for compounding, reactive extrusion, devolatilization, foaming and direct extrusion. Screws and barrels are segmented and made with abrasion- and corrosion-resistant metallurgies as determined by the materials customers are processing.

Coperion GmbH

Customers interested in compounding extrusion equipment need to determine whether they will need high-torque or large-volume capabilities, said Eberhard Dieterich, business unit manager for new machine sales with Coperion GmbH, Stuttgart, Germany.

The company makes only twin-screw compounding extrusion machinery. Its Megacompounder provides the high-torque option, while the Megavolume is the large-volume choice. The selection depends on the feedstock and process requirements.

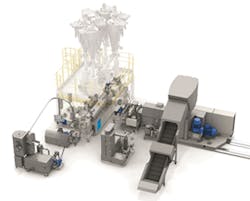

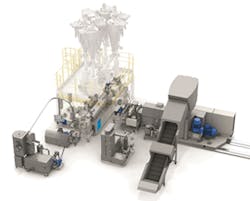

Through a partnership with Erema GmbH, Ansfelden, Austria, Coperion also offers the Corema system for intake and melting of recycling raw materials with Coperion's twin-screw extruder for compounding in additives to improve final material properties. The Erema technology is capable of taking in pieces larger than those that can be fed into a standard extrusion process. The twin-screw extruder serves to increase the value of the final product, and that can increase slim recycling profit margins.

"So instead of taking a plastic recycled stream and just selling it as consumer-grade polyethylene, polypropylene, for example, someone can add mineral filler to it and increase the value of it," said Alex Utracki, director of process technology for Coperion. "So now it's not just recycled plastics which will usually sell for less, but they can add these additives, which will give it certain properties."

With recycling economics being tight, single- screw machines often are chosen for cost reasons. "The twin-screw really shines when we're talking about higher rates," Utracki said. It's also advantageous for value-added processes. "So the twin-screw is a far superior compounding machine than a single-screw could ever possibly be."

Coperion also offers a specific configuration of twin screws for its ZSK MC18 generation of machines that reduces the need for drying with recycled PET. PET is sensitive to moisture when it's melted at processing temperatures, Utracki said. Recycled PET needs to be washed, and that involves a long and expensive run through a dryer. Coperion's system slowly heats the material within the twin-screw during the melting process and removes moisture simultaneously. "So for a recycler, the advantage of that is they can get rid of the final drying step," he said. "It's a cost savings for them."

Allan Gerlat, correspondent

Contact:

American Leistritz Extrusion, 908-685-2333, https://extruders.leistritz/en

American Starlinger-Sahm Inc., 864-297-1900, www.starlingersahm.com

Coperion Corp., 201-327-6300, www.coperion.com

Erema North America Inc., 978-356-3771, www.erema.at

KraussMaffei Group USA, 859-283-0200, www.kraussmaffei.com