Gneuss improves extruded foam process

Gneuss Kunststofftechnik GmbH, Bad Oeynhausen, Germany, has developed a new system to improve the homogeneity of extruded foam.

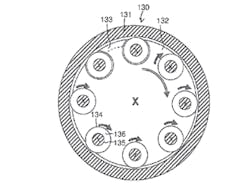

Rotating spindles are used in tandem with mixing screws to reduce variations in melt temperature, creating more uniform cell structure and stronger foams. "A homogeneous temperature of the plastics melt at the outlet nozzle leads to homogeneous cell formation," the patent states.

A foaming agent and other additives are introduced in a first extruder and then the melt is conveyed to a second extruder. Either or both extruders may have multiple screw spindles rotating in the barrel. The spindles also may be located in a connecting extruder. The patent also describes how the two extruders may be connected with a melt line with static vanes or guide plates that perform further mixing of the plastic.

One of the goals of the invention is to improve the mechanical properties of recycled plastics such as PE, PP, PS, PVC, polyamides, polyesters and even bioplastics such as polylactic acid and starches. The new approach could also be used to reduce thickness variations of extruded plastic foams.

Gneuss was founded in 1983 as a specialist in melt filtration and pressure/temperature sensors. Gneuss showed its first extruder, a system designed to process recycled polyester, at K 2007.

Don't look for the new mixing technology at this year's K Show, though. "At this point, this technology is still deep in the realms of R&D and we don't have a timeline for it becoming commercially available," said Monica Gneuss, VP of sales and marketing manager at Gneuss Inc., Matthews, N.C.

Patent Application 20160101546; published April 14

Other patent news:

Optical molding. Engel Austria GmbH, Schwertberg, Austria, has applied for a patent on a multistation molding system for producing optical parts. The stations are arranged in a separation plane, which Engel describes as the surface at which halves of the molding tool meet.

"Arranging the at least three injection stations in a separation plane affords a considerable simplification in terms of technical complication and expenditure which has to be done to convey the respective injection molded layers into the next cavities," the patent states. "In addition in that way the residual heat which is present in the tool can have a positive effect on layer adhesion."

Patent application 20160096297; published April 7

Flash trimmer. Graham Engineering Corp., York, Pa., has received a patent for a modified blow molding flash station where flash and the blow dome can be removed at the same time.

Patent 9,308,685; issued April 12

Simplified control. Mitsubishi Heavy Industries Plastic Technology Co. Ltd., Nagoya, Japan, has applied for a patent covering an injection molding machine control "capable of reducing the load on a user, in relation to display image selection." According to the application, operability is impaired in current systems because of the hierarchical organization on the menu screen. "The selection of the menu button needs to be repeated a number of times corresponding to the hierarchy in order to reach the desired image. … Particularly, the hierarchical configuration may cause the user to forget which hierarchy at which the desired image has been displayed." In the Mitsubishi invention, customizable menu screens are used for specific operators.

Patent application 20160110032; published April 21

Stretch blow molding. Krones AG, Neutraubling, Germany, has developed a new approach to producing bottles that uses less energy. To date, industry efforts to reduce energy use have included compressed-air recycling systems and special bottle forms. The goal of Krones' new approach is to significantly improve the efficiency of the piston compressor within a blow molding machine. A fluid pressure accumulator or other device is used to achieve a more uniform drive load, without force peaks.

Patent 9,314,957; issued April 19

Doug Smock, senior correspondent

Patents and patent applications can be viewed at www.uspto.govHave you applied for or received a patent? Contact [email protected]