Special Report: Hot-runner components target range of applications

New hot-runner products are available for molders, running the gamut from simple to sophisticated valve-gate control, as well as novel components to simplify injection molding operations.

The products include:

• An extension of a tip and nozzle series, a pneumatically driven sequential valve-control system and a gate-bushing insert from Ewikon Molding Technologies Inc., Rockford, Ill.

• A single-drop valve gate for extra-large shot sizes and valve-gate sequence controller from Osco Inc., Rochester Hills, Mich.

• Sequencing controllers and compact hydraulic valve gate cylinders from Incoe Corp., Troy, Mich.

• Valve-gate and hot-tip nozzles from Husky Injection Molding Systems Ltd., Bolton, Ontario

• A manifold valve-gate nozzle and open-flow tipless nut from Mastip Inc., Slinger, Wis.

• A valve gate for very high temperatures from Polyshot Corp. Inc., West Henrietta, N.Y.

• A larger-size, hot-runner nozzle from HRS USA Inc., Greenville, S.C.

• A coolant-free, pneumatically driven line of valve-gate actuators from Mold Hotrunner Solutions (MHS) Inc., Georgetown, Ontario

EWIKON

Ewikon extended its HPS III-MH tip and nozzle series with the introduction of two new designs, created for use in the production of long technical parts such as pipettes or syringe barrels. The new HPS III MH-200 series has higher shot-weight capacity compared to the products in the MH-100 series, yet the size of the nozzle body is the same, says President David Boxall.

The HPS III-MH series is available in linear or radial tip configurations and a choice of three tip versions with angles of 0, 60 and 90 degrees. The linear design comes with a selection of system nozzle diameters that feed four tips, and a choice of four nozzle lengths. The radial version allows users to select one-, two- or four-tip configurations and three nozzle lengths.

Ewikon also offers a new pneumatically driven sequential valve-control system that operates up to eight gates. The Valve Drive Control (VDC) allows users to profile valve-pin opening and closing movements up to three times per injection cycle. A touch-screen control allows individual setup for each valve pin. Pin response time is 2 milliseconds, says Boxall.

The compact VDC unit relies on drive technology similar to that used for the company's stepper motor drive, for precision and repeatability. The controller comes in four- and eight-valve versions, and uses electromagnetic valves integrated into the supply lines, says Boxall. VDC's connector features separate outputs that can be used to operate valves designed either with two solenoids or valves with one solenoid and a spring return.

In addition, Ewikon introduced a gate-bushing insert designed to extend gate life for molders running glass-filled materials. The Insert Gate Bushing (IGB) is manufactured from a sintered metal that is designed for wear-resistance, even when abrasive resins are processed, says Boxall. "Abrasive materials can wear the gate, with a molder eventually experiencing gate flash," says Boxall.

IGB is machined with a gate diameter to match the valve pin it will accompany, and is designed with the gate-seal diameter in mind. This approach makes the insert easier for the molder to install, says Boxall.

The gate life with the use of IGB versus standard gate materials depends on the type of material and parameters of the molding process, says Boxall. The IGB will result in a witness line on the part, created when the valve pin mates with the cavity steel. Depending on the application, the IGB's ease of use can make up for any lines it leaves on the part, says Boxall.

OSCO

Osco is launching a single-drop valve gate capable of handling a 25-pound shot of material, says Peter Rebholz, VP of sales. The unit, tentatively called the Jumbo valve gate, will be the largest within Osco's SVG family of products. The design of the Jumbo is patterned on a 500 series SVG, but features larger pins and larger feed channels with diameters of up to 1 inch.

Osco also offers a full-featured valve gate sequencer (VGS), as well as a MicroVGS control, unit. The pneumatically driven miniature unit is a simpler iteration of the VGS unit, which can handle pneumatic- or hydraulic-driven valve gates, says Rebholz.

VGS versions with varying voltage requirements are available, and eliminate the need for water cooling, using up to 50 percent less energy than other products.

The full-featured VGS can initiate valve-gate action by time, position of the screw or cavity pressure. Many additional programmable features exist from self-diagnostics to multiple open/close sequences within the cycle. It incorporates a detachable control display head, allowing the user to walk with the pendant to the tool to view and test the valve-gate operation from the parting line of the mold.

Unlike the VGS, which can handle up to 16 zones, the hand-held MicroVGS can handle only as many as eight. Also, it initiates gate action by time only.

INCOE

Incoe has introduced its GSCmini multigate sequencer controller created for valve-gate applications that do not require sensor or linear-transducer control. The timer-based, pneumatically actuated product controls and identifies the sequential status of up to eight gates.

GSCmini is lightweight and compact. It has three modes of operation for setting delay and open times for each gate. It is offered in three configurations and can be designed with two, four, or eight pneumatic valves. It comes complete with all required air tubing, air fittings, signal cables and cords. The controller is suited for use in mold trials or sequential gating applications.

Incoe's other offerings include a line of compact hydraulic valve-gate cylinders introduced last year, called HEM. It is suited to back molding of natural fiber mats to produce automotive door trim, says business development director Jim Bott.

The unit is being used in a close-pitched, sequential valve-gating application requiring 20-30 hydraulically driven valve gates that produce rib structures as part of a compression molding or overmolding process. "The physical size of the HEM cylinder allows us to put the hydraulic actuation cylinder well within a 37mm pitch," says Bott. The HEM cylinder is combined with Incoe's Direct-Flo series nozzles for this application. The closing force of the cylinder is equal in power to larger cylinders, says Bott.

The miniature HEM cylinder features im-proved thermal separation. It is mounted onto a water-cooling block that isolates the device from the manifold. The cylinder can be removed from the cooling circuit block, which simplifies maintenance, says Bott.

The design of the HEM cylinder prevents oil from reaching critically high temperatures, which protects moving parts and seals and eliminates the need for cooldown once production work is complete. The smaller dimensions of the cylinder create space for supply lines. Outlets for the cooling lines can be arranged in four directions, which provides options for possible gating points, says Bott.

HUSKY

Husky has extended the range of its Ultra Helix series of valve-gate nozzles with two new sizes this year. The nozzle series is suited for demanding medical applications.Last year, Husky introduced the Ultra Helix valve-gate nozzle line, designed for direct gating of parts with gate vestige as slight as an ejector pin mark. Husky developed manufacturing technologies that guarantee stem-to-gate orifice concentricity, which minimizes mechanical wear of valve-gate components, says Craig Reynolds, director of business development. A new heater design provides a consistent thermal melt profile that allows the processing of a wide range of materials. The valve-gate nozzle is constructed to extend gate life to millions of cycles.

The new nozzles include the Ultra Helix 350, designed to handle 5-20 grams per second of material, and the Ultra Helix 750 nozzle that can process 50-250 grams per second.

Husky offers two variations of the valve-gate nozzle, including the Ultra Helix VG. In the Ultra Helix VG, all critical gate geometry is contained within the tip, which has an outside diameter of 3mm.

The Ultra Helix VR version can be retrofitted to existing cold halves. It virtually eliminates mechanical wear by keeping the valve stem centered on the gate, says Reynolds.

Husky says the design of the Ultra Helix simplifies cold-half machining requirements for mold integration, which shortens mold-validation times. "Years ago, we determined that in order to deliver superior gate vestige quality and thermal balance from drop to drop, cavity to cavity, standard manufacturing practices could not be used, so we created and developed new approaches for this valve-gate design," says Reynolds.

Husky has also developed new heater technology and new tip designs for its Ultra SideGate hot-tip nozzles. The new designs better handle high-temperature technical resins like cyclic olefin copolymer, polyoxymethylene, polybutylene terephthalate and polyamide. Ultra SideGate is ideal for deep-draw parts such as pipettes, syringe barrels, hinged closures or parts where only side gating is possible but gate quality is critical.

Ultra SideGate incorporates spring-loaded components that ensure a complete seal between tip and nozzle and between nozzle and manifold for leak-proof operation. It produces a gate vestige on the finished part around 0.05mm, depending on the resin. The nozzle is offered in one-, two- and four-tip configurations. Users can choose from angled or straight tips with tip distances that can vary from 55mm to 63mm.

MASTIP

Mastip has introduced a new manifold valve-gate nozzle for applications that require medium to large shot weights and cosmetic gates. The new MVG55 is designed as a pneumatically actuated valve gate that can be incorporated into Mastip's BX series nozzles as part of a sequential valve-gating system. It operates with reduced molding pressures, providing lower mold filling stress and lower gate-cooling requirements while increasing the processing window, says Dave Shirley, Mastip's GM for North America.

MVG55 can process unfilled or filled, as well as difficult engineering-grade materials, resulting in parts with increased dimensional stability and improved part strength and appearance. Users have a choice of gating options, and the standard nozzle spacing of 95mm can be modified to a narrower pitch of 74mm. The pneumatic circuit is integrated with the back plate, which itself can be as thin as 55mm to minimize overall stack height, says Shirley.

Mastip also developed its new YCN-type, open-flow tipless nut for its X range of nozzles. With the nut, heavily filled or shear-sensitive materials can be processed where straight-through, open-flow molding is required. "Typically, our hot-runner nozzles incorporate a tip from our range of tip configurations, which sits precisely in the gate to control gate vestige," says Shirley. This design is used in applications where the cosmetics of the gate are not a concern, so the tip insert is not required.

The YCN open nut is designed to minimize melt shear, reduce overall pressure drop through the gate and provide a broad and repeatable process window, says Shirley. It is offered in a choice of three internal gate/taper profiles to suit a wide range of materials and thermal requirements.

POLYSHOT

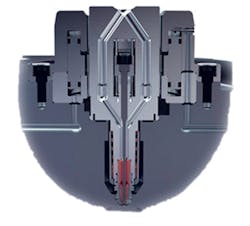

Polyshot President Doug Hepler says that typically high-temperature resins and hot-runner systems don't mix well. But the company's pneumatically driven Single Nozzle Valve Gate, introduced last year, now handles even higher temperatures and shot sizes from 10 to 500 grams.

The Single Nozzle Valve Gate, which was initially rated to handle material temperatures up to 750 degrees Fahrenheit, can be used to directly gate resins heated up to 875 Fahrenheit, says Hepler. The nozzle can handle the higher-temperature materials due to how the component is made, via the company's proprietary vacuum-brazing technique. Hepler says nozzles with gun-drilled melt channels can have a hard time handling the resins if the melt channels become misaligned.

The compact, pneumatic valve gate is designed with the entire assembly, including the actuating cylinder, contained within the mold-locating ring. The nozzle uses fewer components than competing designs. Typically, a single-nozzle valve gate uses a piston with a diameter of 0.75 inch. Together with shop air pressure — usually about 100 pounds per square inch — a piston like this generates 75 pounds of pin force, says Hepler. However, the Polyshot nozzle has an annular ring that features 4 inches of projected surface. This design, combined with shop air, generates 400 pounds of pin force, resulting in consistent valve sealing.

HRSflow

HRSflow has extended the range of standard hot-runner nozzles in its Multitech line with a new, larger size that handles higher shot weights and is suited to parts requiring thicker walls. The new MTR thermal gate nozzle is the fourth size in the Multitech line and handles shot weights from 8 to

40 grams, says President John Blundy.

MTR is constructed with stainless steel and employs an end ring and screw-in nozzle to create a system that seals the nozzle on the cavity and tightens the tip to the nozzle. A material with low thermal conductivity is used in the end ring to ensure good insulation between nozzle and cavity while delivering precise thermal control at the gate, says Blundy.

MTR handles a wide range of commodity materials at high flow rates for use in multicavity applications that require rapid cycle times and fast color changes.

MHS

MHS has expanded its line of cooling-free, pneumatic Black Box valve-gate actuators with the new VA6015. "The Achilles' heel of a valve gate is the water cooling that is required to protect the seals in the piston," says President Harald Schmidt.

The new cooling-free technology uses zero-maintenance actuators. In high-temperature applications, in which mold temperatures can reach 400 degrees Fahrenheit and material-processing temperatures can reach 800 degrees, cooling-performance reductions can lead to a breakdown or inconsistent operation of the valve gate, says Schmidt. The new Black Box actuator eliminates this problem, says Schmidt.

The coolant-free operation also eliminates the need for cooling lines in the hot-runner assembly. This means there are fewer cutouts in the mold plates, which increases the integrity of the mold, mold base and hot runner, says Schmidt.

The design of Black Box, part of the company's Rheo-Pro line of hot runners, is also ideal for stack molds, where the actuator can be placed inside the middle block and operate without lubrication, seals or maintenance. MHS offers the Black Box actuator in two sizes. It is suited for use with all valve-gate hot-runner applications.

Mikell Knights, senior correspondent

Contact:

Ewikon Molding Technologies Inc., 815-874-7270, www.ewikon.com/en

HRS USA Inc., 864-627-5373, www.hrsflow.com

Husky Injection Molding Systems Ltd., 905-951-5000, www.husky.co

Incoe Corp., 248-616-0220, www.incoe.com

Mastip Inc., 262-644-9400, www.mastip.com

Mold Hotrunner Solutions Inc., 905-873-1954, www.mhs-hotrunners.com

Osco Inc., 248-852-7310, www.oscosystems.com

Polyshot Corp. Inc., 585-292-5010, www.polyshot.com