Wasp printer produces large parts efficiently

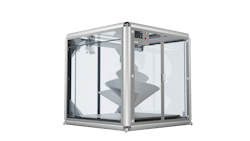

Cubo HDP This new compact, large-scale Wasp 3D printer for pellets has a clamping system that enables the efficient production of large parts, even at high volumes. Unlike a heated bed, which on very large surfaces can cause warping, detachment or uneven heating, the clamps keep parts perfectly secured throughout the entire printing process. Designed for environmentally friendly manufacturing, the printer has a rechargeable filtration system, as well as a powder recirculation system that keeps particles in constant motion, ready for printing without waste. Also, it has an auto-feeding system monitored by a capacitive sensor that halts printing once the material supply is exhausted.

What’s new? The machine, first displayed publicly in September at the IAAPA Expo Europe in Barcelona, the leading European event for the attractions and leisure industries.

Benefits The ability to print at large scales with lower material costs, as well as flexibility, efficiency and ease of use. The machine can print difficult-to-process materials, like PET-glycol (PETG), as well as non-proprietary materials and recycled composites. In particular, it enables the use of 100 percent recycled materials to produce more sustainable parts. The new printer’s powder recirculation system maximizes the reuse of recycled material, and it is compatible with Wasp’s Rigenera 3D extrusion system, which allows users to print directly from in-house recycled shredded plastics.

Wasp, Massa Lombarda, Italy, 39-0545-87858, www.3dwasp.com

Vital Statistics

|

Print volume |

Around 3.9 feet by 3.9 feet by 3.9 feet |

|

Average power consumption |

450 watts |

|

Maximum power-on load |

1 kilowatt |