1000 Kelvin gives AI assist to 3D printing design

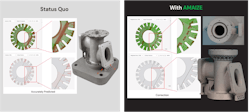

Amaize This software from 1000 Kelvin uses artificial intelligence to generate 3D printing strategies to ensure that manufacturers can turn out high-quality parts with complex designs from the first print on. Users can upload a print file to the Amaize cloud, which analyzes the part and automatically corrects thermo-mechanical issues by optimizing the scan strategy and process parameters.

What’s new? The software, which is compatible with metal laser powder bed fusion printing and is expanding to selective-laser-sintering and direct-energy-deposition processes for polymers. Among Amaize’s first successful users is a California-based rocket launch provider, which was struggling to 3D print a critical part due to problems with support structures and overheating. In addition to the rocket company, companies in the energy, aerospace and contract manufacturing industries have adopted Amaize.

Benefits The generation of optimal print recipes and processes, easier 3D printing, and improved efficiency and reduced waste associated with the processes. The software makes possible the manufacture of 3D parts printed right the first time. It eliminates the need for costly finite element simulation software and multiple physical iterations. With Amaize, the rocket company was able to digitally iterate solutions to its thermal management problems, and print parts with improved surface quality and performance. In particular, the user was able to substantially decrease the need for support structures, reducing costs more than 30 percent.

1000 Kelvin LLC, Huntington Beach, Calif., 714-292-4675, https://1000kelvin.com

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.