Rize executives say printing offers personalization at push of a button

When it comes to being able to vary colors or physical characteristics of parts, such as rigidity or flexibility, injection molders have a few options — overmolding, multi-material molding, post-molding assembly.

But the strategies only go so far.

Molders can’t selectively color each face of a Rubik’s cube, for instance. But the 3-D printers offered by at least one company can.

The Rize printers extrude engineering-grade plastic powder layer by layer. Their current hardware allows them to apply as many as six different additives selectively, one voxel — the three-dimensional equivalent of a pixel — at a time, with the possibility of creating surface characteristics, such as color, and performance properties, such as, hardness, softness, even electrical conductivity. Rize is planning to release its newest printer, the 7XC, soon.

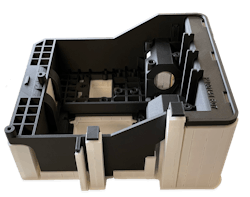

Using composite materials blended with glass or carbon fibers, the Rize printers can produce parts with geometries and properties that could not be injection molded in one piece; they also can be used for lightweighting.

As Kalambi and company co-founder Eugene Giller readily admit, the printers aren’t as fast as injection molding machines — but what they lack in speed, they make up for in versatility.

“You can put in functional inks and additives. Through the 3-D print process, we can change the material property at what is called a voxel level,” Kalambi said. “So, suddenly, what you have is, if you want something softFor full traceability, Rize’s printers can mark parts with unique numbers or bar codes linked to further information or instructions.

Customizability, vivid details

In a video call, Kalambi and Giller discussed what they see as some of the chief advantages of 3-D printing: the opportunity to customize parts and produce them with great detail. Giller showed off a number of parts displaying these advantages — from a model of a bone that could be used by doctors prepping for surgery to facsimiles of sushi and a Fanta soda can, complete with eye-popping orange, blue and green details.

“The beauty of 3-D printing is that you can play with materials. You can literally change material properties as the printing processes on. And when the part comes out of the printer, it can be a completely different material from what went in,” Kalambi said. He refers to this as a “metal material” — a material that exhibits entirely different properties than the original plastic powder used in the process.

Industrial users typically print jigs, fixtures and replacement parts.

Meanwhile, at schools like the Virginia Tech, people are using Rize printers to study many aspects of manufacturing.

“People are looking at how does 3-D printing integrate into the workflow, which includes robotics. For example, you want to print gripper fingers, things that are going on a robot to make it more efficient or have traceable kind of applications, where you are able to put a digital thread on a part so that you can see the part both in its physical, as well as in its virtual, context,” Kalambi said.

Finally, among the company’s biggest segments of users are health-care professionals, drawn by the printers’ precision and ability to manufacture parts without producing fumes, said Giller, a polymer scientist who works as Rize’s chief science officer.

Doctors can use such 3-D printing to make tailor-made implants, as well as models of organs or bones.

“They are looking what can be done on point of care and personalization. So, you know, I need my heart to be printed in terms of seeing any issues that may be there, or my bone to be printed, and that's personalization, so it's more personalized health-care kind of applications that are being done,” Kalambi said.

Better, stronger, faster

As an example, Giller talked about Rize’s work with a toy company that envisions using printers to supply toys customized for individual children.

It’s one application that demonstrates the dream for 3-D printing: “Basically, it's like this magic replicator on a spaceship, you need something, you press a button, you get it. That’s what everyone wants,” Giller said.

Star Trek’s replicator hasn’t hit the market — yet — but 3-D printing’s evolution Is underway. Printer customers increasingly want machines that are easier to use, faster and even more versatile, according to the Rize executives.

“They want everything. They want a magic button. They want to design something, they want to press ‘Start,’ and they want to get it in two minutes,” Giller said.

According to Giller, Rize is working on its next generation of printers to make them more capable of printing multiple parts or a variety of parts at the same time. Before the release of the 7XC, set to hit the market in mid-April, the largest printer in the company’s stable was the XRize, weighing in at 137 pounds, and measuring 21.4 inches by 36 inches by 25.4 inches.

Referring to the bone model made by a Rize printer, Kalambi explained that printing software also must evolve, to suit the design-and-manufacture-on-demand sensibilities of users.

“We work with a company, for example, to take CT MRI scans, which are digital in nature, and then make them into 3-D printable files, so that you can get things like this bone that you see here, this orthopedic part, which is used by surgeons for pre-surgery planning, that piece of software is also evolving, where people are looking at how to drive the scan-to-print automation,” he said.

Whether models of bones or food, Invisalign braces for teeth, or furniture, parts made by 3-D printing will continue to raise expectations for products perfectly tailored to the needs of the end user.

“It’s exciting. In the future, I can see you design your own shoes, or you design your whatever you want. ... Or you scan your hand. You want a stick shift, and you want to make sure that it fits your hand and your hand only, and that you perfectly fit it. I think that’s where the future is,” Giller said.

Karen Hanna, associate editor

Contact:

Rize, Concord, Mass., 978-699-3085, www.rize3d.com

New Rize 7XC offers batch processing

By Karen Hanna

In a race between 3-D printers and injection molding machines, it’s easy to identify the roles of tortoise and hare.

But makers of 3-D printers say the technologies are coming up with strategies to compete. Batch processing — in which multiple parts can be manufactured and subjected to post-processing simultaneously — is one approach. Among the newest products in the field is Rize’s latest and largest printer, the Rize 7XC; a new series of powder-bed-fusion-based 3-D printers from Stratasys; and a couple new technologies offered through 3DChimera.

Rize co-founder Eugene Giller calls batch processing the industry’s Holy Grail. A polymer scientist who works as Rize’s chief science officer, he sees the Rize 7XC as an important milestone.

“We are working on creating a batch process, where the process itself may take, for example, 50 hours, but you can produce maybe 50 units at once in that time. And that’s where the Holy Grail for manufacturing comes in,” he said. “If you need a small-volume production part, whether it’s just one part or 50 [or] 100, you have options either way. Smaller 20-minute parts can be printed on the Rize 2XC and larger one-hour parts on the Rize 7XC.”

At 14.6 inches by 15.4 inches by 17.7 inches, the Rize 7XC’s build size is “massive,” according to the company. The printer represents the joint efforts of Rize and Sindoh Co. Ltd., a 3-D printer maker based in Seoul. It pairs Sindoh’s 7X large-format, dual-nozzle 3-D printing platform with Rize’s composite and carbon-fiber-reinforced materials. According to Rize, it can create parts with high tensile strength and thermal dimensional stability, along with chemical and moisture resistance.

Ideal for manufacturing jigs, tooling and fixtures, the $19,995 Rize 7XC can print without operator intervention for significant amounts of time.

It hit the market in mid-April.

“Our customer, a major electronics manufacturer, used the Rize 7XC to create large jigs, called nests, for their automotive electronics assembly processes — parts that need high strength and durability,” said Roberto Jacobus, director general at Industrias VIWA, a provider of CNC and 3-D printing services based in Jalisco, Mexico.

Jacobus’ customer can build nests in just two or three hours — a significant upgrade over the week it used to take with traditional machining processes. The nests also have lasted longer than previous jigs made with ABS on another kind of printer. Made using Rize’s Rizium carbon-fiber material, they measure 12.6 inches by 11 inches.

The 3-D printer’s build volume makes production manufacturing using the additive manufacturing process more cost-effective than ever, Giller noted.

“On the Rize 7XC, a part that takes one hour to print and less than one minute to post-process will cost the user around $1 a piece. For a batch of 500 parts, that means it costs only $500 and takes about 50 hours or about two days,” he said. “Regardless, it’s way less expensive than with injection molding, where creating the mold will take three to four weeks at the cost of 15 to 20K, and the cost per part will be at least an additional 50 cents more without amortization of the mold.”

It’s another step forward in the additive manufacturing quest. “The Rize 7XC makes additive manufacturing capability rugged enough for industrial 3-D printing needs, yet safe and affordable, too,” Rize CEO Andy Kalambi said. “Finally, manufacturers can apply the promise of additive manufacturing to creating agile and distributed supply chains where the ability to generate a needed part, tool, jig or fixture takes a fraction of the time of traditional processes.”

Technological advances are allowing 3-D printers to close the gap.

“Even if somebody needs 1,000 parts, additive manufacturing can do it very cheaply,” Giller said.

Vital Statistics

| Rize 2XC | Rize One | XRize | Rize 7XC | |

| Printer dimensions | 1.6 feet by 1.5 feet by 1.9 feet | 1.8 feet by 3 feet by 2.1 feet | 1.8 feet by 3 feet by 2.1 feet | 2.8 feet by 2.7 feet by 5.5 feet |

| Printer weight | 68 pounds | 135 pounds | 137 pounds | 374.8 pounds |

| Build volume | 8.9 by 7.9 by 11.8 inches | 12 by 8 inches by 6 inches | 12 by 8 inches by 8 inches | 14.6 by 15.4 inches by 17.7 inches |

Related stories

From prototypes to production, manufacturers harness evolving 3-D technology.

Printing's advantages shine in pandemic, says 3DChimera co-founder.

Stratasys to launch production-scale 3-D printers.

Industry survey finds use of AM is expanding beyond prototyping and R&D.

3YourMind sees a growing market for printing spare parts.

Jabil develops a new high-strength filament to meet customer demand.

Additive manufacturing grew in 2020 despite pandemic, says Wohlers Report.

About the Author

Karen Hanna

Senior Staff Reporter

Senior Staff Reporter Karen Hanna covers injection molding, molds and tooling, processors, workforce and other topics, and writes features including In Other Words and Problem Solved for Plastics Machinery & Manufacturing, Plastics Recycling and The Journal of Blow Molding. She has more than 15 years of experience in daily and magazine journalism.