Hot-runner components embrace innovation

Hot-runner innovations at NPE2018 ran the gamut, from full systems to new and redesigned nozzles, tips, valve gates, manifolds, heaters and melt channels. The goals of the latest offerings include conquering tough materials and increasing throughputs and uptime. Modularity and compact size were among the themes on the show floor.

MOLD-MASTERS IMPROVES GATES AND MANIFOLDS

Mold-Masters introduced to the U.S. its SeVG+ servo-electric valve gate and its Slim-Stack hot-runner manifold for stack molds with limited space. It also enhanced its Dura+ hot-runner system, which is designed to handle abrasive and corrosive resins such as PC, PC/ABS and polymethyl methacrylate for molding automotive lenses.

To enhance part quality and optimize mold balance, the SeVG+ individually controls each valve pin in valve-gate flow sequences for up to 16 cavities, said Thomas Bechtel, sales director for packaging and medical markets. It allows for precise and immediate adjustment of a valve pin based on its position, speed, protrusion, timing and sequence. It can sequence as many as 10 operating steps in the movement of the valve pin.

SeVG+ provides complete actuation control that is not possible with traditional operation. It consumes a fraction of the energy used by a traditional hydraulically actuated system, Bechtel said.

The Slim-Stack manifold reduces the stack height of the manifold by up to 40 percent compared to a conventional manifold, he said. Slim-Stack manifolds are suited for molding packaging, personal care and medical parts, caps and closures. They incorporate a larger runner bore and shorter runner lengths vs. conventional manifolds. The stack-height reduction minimizes pressure drops.

The Slim-Stack accommodates front-mounted valves that are accessible from the mold parting line for maintenance. This eliminates the need to remove the entire system, saving time and money.

Introduced in 2015, the Dura+ has been updated so that it can process resins better and handle a wider range of materials. The updates also increase its durability and minimize contamination and part defects. The new nozzles are made from stainless steel, and hot runners made from the material also are available. Stainless steel provides excellent corrosion resistance, preventing part imperfections that can occur due to reactions between the steel and corrosive resins.

The stainless-steel system also features a highly polished runner finish that helps produce high-quality parts, reduces scrap and extends the system's life.

The Dura+ incorporates flexible tubular manifold heaters and dual high-temperature thermocouples. With them, the system experiences no more than a 10 percent variation between set point and actual temperature.

The Dura+ reduces the amount of pressure drop by up to 27 percent, resulting in a wider processing window. In field testing, the new system delivered 22 percent faster cycle times and a part scrap rate of 0.8 percent.

The Dura+ series of hot runners handles shot sizes from 50 grams to more than 3,500 grams and comes in nozzle lengths from 28mm to 1,000mm. An optional flanged design allows for the easy installation of a nozzle onto an angled manifold.

INCOE LAUNCHES SLIM NOZZLES

At NPE2018, Incoe touted the U.S. debut of its Slim-Flo nozzle, which incorporates its Seal-Fit leakproof technology. The nozzles, which thread into the manifold, save energy compared to compression-style nozzles because they don't touch the mold at the nozzle/manifold transition, business development manager Jim Bott said.

In addition, the positive threaded connection between nozzle and manifold minimizes the risk of leakage between the two components, he said.

The Slim-Flo nozzles, which have a 5mm-diameter flow bore, are part of Incoe's Direct-Flo line of modular hot-runner systems. The nozzles are screwed into the manifold, creating an all-in-one system that minimizes cavity distances to promote more efficient molding with a multicavity tool. Incoe is applying the space-saving Slim-Flo design to its Direct-Flo (DF) 8 nozzle series, which has an 8mm-diameter flow bore.

Incoe also developed a new slim model of its DF 8 nozzle that incorporates the company's redesigned MultiPower heater. The redesigned heater uses two heating zones rather than the previous three, which cuts costs yet delivers uniform thermal control over the entire length of the nozzle. The MultiPower heater replaces the bulkier BH and MH heater combination that previously had been used in the DF 8.

The MultiPower heater and associated thermocouple can be changed easily. All heating wires are positioned under the heater case for protection. The compact nozzle and slimmer heater simplify mold cutout requirements.

The special DF 8 nozzle handles shot weights from 1.06 ounces to 1.1 pounds, depending on the melt viscosity and nozzle tip. It is useful when gate points are deep in a mold.

HRSFLOW ADVANCES GATE DESIGN

HRSflow launched its HPgate, a new hardened metal valve gate that is screwed into the mold and can be replaced easily.

The insert allows the user to manufacture parts with a high-quality finish at the gate without flash. The HPgate addresses the difficulties molders face when using conventional gates. Users of conventional gates have to adjust for narrow gate dimensions and flow variations that impact the symmetry between the gate and needle valve pin, said Italo Bincoletto, GM of HRS Hot Runner Systems NA Inc., the company's North American unit in Windsor, Ontario.

With a conventional gate configuration, a plastic layer can form at the gating point. This layer is torn off from the part when the mold opens and could lead to flash, a problem that the HPgate minimizes. Incorporating a cylindrical needle closure reduces the time required to optimize the process and attain high-quality parts.

Due to the hardness of the insert, the HPgate allows mold makers the option of possibly choosing softer, less expensive steel for the mold plates. HRSflow said another advantage is that the needle has a conical contact surface that better controls its temperature.

OSCO ADDS NOZZLE OFFERINGS

Osco has added sizes to its lineup of Multiple Gate Nozzles (MGN). The MGN incorporates its CVT series of externally heated tips.

The MGN series minimizes residence time and delivers balanced melt flow while controlling temperature at each gate. The nozzles are offered in direct-feed or manifold designs and feature replaceable heaters and tips wit variable styles. They can process a range of temperature-sensitive or unusual filled materials, such as a 20-percent-copper-filled resin, VP of sales Peter Rebholz said.

The new MGN-G 50 is ideal for molding small parts from commodity resins. It comes with a choice of two or three gates and nozzle diameters ranging from 0.343 inch to 0.406 inch, he said. Centerline spacing is 0.3 inch, smaller than the 1-inch center spacing required by some competing nozzles.

The MGN-T 50 uses externally heated drops to achieve longer-length parts, Rebholz said. It handles up to four gates and has nozzle diameters of between 1 inch and 1.812 inches. Users have a choice of three tip styles for a wide range of applications.

As part of its HSN series of nozzles, featuring two zones of temperature control, Osco also rolled out new hot-sprue nozzles designed to handle a wide range of materials, from commodity resins such as PP to engineering resins like PEEK, while fitting into a 0.75-inch bore.

The Series 35 HSN nozzle has a 0.75-inch diameter cold-sprue bushing that provides melt flow equivalent to a 1-inch-diameter sprue bushing, Rebholz said. It is designed to replace 0.75-inch-diameter cold-sprue bushings, while the Series 75 HSN nozzle is designed to replace 1-inch-diameter cold-sprue bushings. Both feature larger feed channels for their respective bore sizes than any other nozzle.

HEITEC x-SLIM NOZZLES HANDLE LARGE SHOT SIZES

The X-Slim line of hot-runner nozzles for large shot weights from Heitec Heisskanaltechnik GmbH, Burgwald, Germany, now comes in a standard valve-gated version and boasts a larger selection of nozzle diameters, said Paul Boettger, owner and president of the firm's North American representative, Technoject Machinery Corp.

While the nozzle body remains skinny, X-Slim nozzles feature an enlarged melt-flow channel to accommodate more material, Boettger said. To increase melt flow in the updated version of X-Slim, the company stripped down the nozzle's needle valve pin, nozzle body wall and heater element.

The nozzle now comes in three diameters. Each size also comes in three standard lengths, from 100mm to 350mm. Melt-channel diameters of 4.5mm to 8mm are available.

The nozzle is suitable for use with a wide range of resins and maintains the optimal temperature for the material being processed. It handles shot weights from 0.02 gram to 1.1 pounds, Boettger said. It requires an installation bore of between 11mm and 20mm and can be used with cavity spacing as narrow as 28mm.

A selection of replaceable tips and thermocouples allows the nozzle to be used for packaging, medical and technical applications.

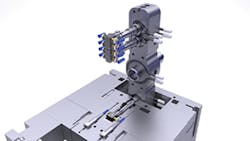

HUSKY UNVEILS NOZZLE FOR TIGHT SPACES

Husky introduced its Ultra SideGate Inline nozzle. According to the company, it allows for direct sidewall gating of high-quality parts that would otherwise require gating with a cold runner.

The nozzle is ideal for part spacing as small as 18mm. It can produce a gate with a vestige as small as 0.05mm, depending on the resin. The patented design features a replaceable tip that is separate from the nozzle. It improves cooling and eliminates the need for split melt-flow cavities in favor of a single cavity. Tip-to-tip spacing can be as small as 55mm.

The nozzle, like the conventional Ultra SideGate, provides easy access to the nozzle tip and allows for in-machine maintenance. Ultra SideGate Inline handles a wide variety of resins, including difficult-to-mold materials such as PC. It is suited for molding deep-draw parts such as pipettes and syringe barrels or hinged closures or smaller parts where gate quality is critical and only side gating is possible.

The nozzle incorporates Husky's UltraSeal technology, which features a spring-loaded tip for fast tip removal in the press and leakproof operation. It delivers precise thermal control and is available with individual tip temperature control for even more precise thermal control. It can shut off melt flow to individual cavities.

The Ultra SideGate Inline is available in angled or straight tips with variable tip distances from 55mm to 63mm. It can be configured with one or two tips per nozzle.

MANNER DEVELOPS NOZZLE FOR CAPS AND CLOSURES

Manner has extended its Slimline series of valve-gated nozzles with a version for caps and closures. The new version is suited for producing high-quality polyolefin parts using molds with limited space for multiple cavities. In general, it is suited for high-volume production of complex small and medium-sized parts.

The nozzle combines a basic body and a tip that handles a wide range of materials, including engineering resins. It features a new insulating ring, a patent-pending temperature-control element and other specially integrated components that ensure homogeneous temperatures and excellent thermal separation of the nozzles from the mold, director of sales Arno Pfaff said.

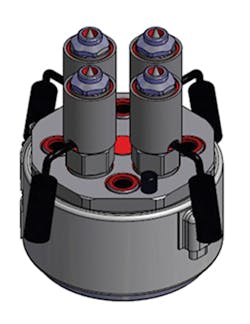

EWIKON SYSTEM TARGETS SMALL-PART MOLDING

The L2X-Mikro, Ewikon's drop-in hot-runner system for direct gating of parts as small as 0.05 gram, made its U.S. debut at NPE2018. Inspired by an earlier high-cavitation system, the L2X-Mikro has a more compact manifold with fewer drops to handle small shot sizes, President David Boxall said. Thanks to its short flow paths, which are designed to handle a small volume of flow, it can process thermally sensitive engineering and commodity resins.

The system features a 61mm-by-48mm manifold in three standard, compact layouts with two, four or six pre-installed nozzles that fit the most commonly used mold sizes for small presses. The system also is offered as a hot half in two standard sizes.

Each nozzle has a leakproof, screw-in connection that reduces space requirements in the mold.

Ewikon's Slim hot-runner nozzles have a 10mm outer diameter and 3mm internal flow channel for the melt. Each nozzle has an integrated thermocouple and is heated directly by a compact coil heater, resulting in very stable heating that's maintained to within 1 degree Fahrenheit of set point, Boxall said. The design also improves heat control in the gate area.

Mikell Knights, senior staff reporter

Contact:

Ewikon Molding Technologies Inc., Rockford, Ill., 815-874-7270, www.ewikonusa.com

HRSflow,

Byron Center, Mich., 616-228-6900,www.hrsflow.com

Husky Injection Molding Systems Ltd.,

Bolton, Ontario, 905-951-5000,www.husky.ca

Incoe Corp. USA, Auburn Hills, Mich., 248-616-0220, www.incoe.com

Manner USA Inc.,

Lawrenceville, Ga., 770-449-1820,www.maenner-group.com

Mold-Masters Ltd.,

Georgetown, Ontario, 905-877-0185,www.moldmasters.com

Osco Systems Inc., Rochester Hills, Mich., 248-852-7310, www.oscosystems.com

Technoject Machinery Corp.,

Bolton, Ontario, 905-951-7144,www.technoject.com