Additive manufacturing joins smart factory wave

Additive manufacturing technologies are exploding onto the scene, as companies launch new designs that tackle traditional limitations involving speed, materials and part size. Just as Industry 4.0 capabilities are transforming other aspects of plastics processing, the smart factory movement, emphasizing information sharing, equipment interoperability and networking, is widening the possibilities for additive manufacturing.

David Tucker, HP's head of market development for 3-D printing, sees a "complete digital transformation of the $12 trillion global manufacturing industry." With HP's Multi Jet Fusion printers, users last year made more than 3 million parts. Tucker, who will co-present, "Multi Jet Fusion vs. Traditional Mass Production Methods," from 1:15 to 1:45 p.m. May 9 at NPE2018, believes digital advances will make 3-D printing a viable means for both prototyping and full-scale production on a single platform.

"3-D printing is completely reinventing the way things are conceived, designed, produced and distributed," he said. "Its many advantages over traditional manufacturing include faster time to market, lower start-up costs, simplified logistics and lower carbon footprint. But, among the most important advantages is design efficiency or flexible manufacturing — the ability to accommodate changes or modifications within the manufacturing process in real time."

Industry 4.0 will be on full display at NPE, with many additive manufacturing-related companies, including Stratasys, Carbon and Rize, clustered within the 3D/4D Printing Zone.

ARBURG

While some companies have begun to see additive manufacturing technologies as a complement to traditional injection molding, Arburg has moved one step further — to combining the processes. During NPE, Arburg will present a sophisticated marriage of technologies with Industry 4.0 in what it calls a "practical example."

In Booth W1325, Arburg will demonstrate an IT-networked and fully automated production line for making business card holders. A six-axis robot will link an Allrounder injection molding machine with its Freeformer additive manufacturing system. An individual bar code is lasered onto the molded part and the Freeformer additively applies ABS to create the raised lettering. For the automatic opening and closing of the cowl, the Freeformer and robotic system communicate via a Euromap 67 interface.

"By combining injection molding, additive manufacturing and Industry 4.0 technologies, customer requirements can be integrated directly into the value chain to individualize and enhance high-volume parts," said Friedrich Kanz, president and CEO of Arburg Inc. The objective of Industry 4.0 is to make production more flexible, to achieve the best possible machine utilization and to make production processes more transparent.

"An important step in this regard is the digitalization of business processes and services," he said.

In addition to the Freeformer setup, Arburg also will feature six new software packages for use with its injection molding machines. The first software package, 4.set-up, provides guided setup and active support to machine operators. Another package, 4.start-stop, facilitates production startup, reduces the number of startup parts and increases production capacity. Arburg's 4.optimisation is designed to enhance part quality and reduce unit costs. Its 4.production gives experienced operators greater flexibility and freedom when they are programming functions. In particular, it facilitates work with special processes and complex mold technology. In addition to the others, 4.monitoring provides detailed process and quality monitoring, as well as seamless process documentation. Through 4.service, customers receive remote assistance via online support.

The packages run on Arburg's ALS host computer, a manufacturing execution system, or MES, designed for use by injection molding companies. ALS allows users to trace and archive orders and batches, plan for maintenance and create reports relating to overall equipment effectiveness.

STRATASYS

Through cloud-based communications, users of Stratasys' fused-deposition-modeling (FDM) printers can tie the machines into their technology programs and shop-floor control systems to reduce inventory and better track the supply chain.

In Booth S20159, Stratasys will be demonstrating its J750, a full-color, multimaterial 3-D printer, and its F123 series of 3-D printers.

In the last year, Stratasys has added new state-of-the art printheads to the J750 to improve print quality. The printheads have a 40 percent longer life span than the previous generation. The improved head assembly creates less head delamination, while a new, finer filter — 20 microns, compared to 30 — and uniform heating across all print nozzles mean less clogging. The company also has enhanced the material range and color matching of the J750 so that it now more accurately converts Stratasys' color from its GrabCAD software to the printed part.

In the future, Phil Reeves, the company's VP of consulting, anticipates that users will be able to design and manufacture their own customized parts, including fashion accessories and eyeglasses. Software advances will make that possible. "This data needs to be pre-processed and automatically fed into the 3-D printing production environment. Our GrabCAD print and voxel print software tools are laying the foundations for this workflow."

CARBON

Software also is one of the key offerings within the portfolio offered by Carbon, which makes printers that use light to solidify ultraviolet-curable liquid resins. The company is also known as Carbon.

"We are a beneficiary of Industry 4.0; Carbon has been built from the ground up as an Industry 4.0 company," said Luke Kelly, VP of operations. "The company has incorporated big data, robotics and cloud computing to leverage what it can do for our customers. Our mission is to maintain a digital thread."

That means the process starts with digitally capturing a product's design, which speeds printing because there is no need for analog input or output of data.

In Booth S24160, Carbon will display its Carbon's Digital Light Synthesis technology used to make midsoles for shoes. The printers also are used to make the Vitamix durable microfluidic nozzle for rinsing and cleaning Vitamix blenders in commercial settings.

Both of these applications employ internet-connected hardware, next-generation software and digital design to create products not previously possible with 3-D printing, according to Carbon.

Carbon's software enables designers to come up with dozens of iterations and simulate its production and functionality using tools like finite element analysis (FEA). From there, the design is transferred to internet-connected hardware that produces the midsoles.

By combining multiple aspects of Industry 4.0, Carbon said the printers effectively eliminate the prototyping and tooling stages used in traditional manufacturing methods like injection molding.

RIZE

The ability to produce functional end-use parts is one of the guiding aspirations of 3-D printer makers and users, said Julie Reece, VP of marketing for printer-maker Rize. Using a printer should be like scheduling an Uber. "Just press 'print,' and get your part, wherever you need your part."

To that end, Reece said her company has integrated its printers with the 2018 version of a 3-D printing design software package from Dassault Systèmes SolidWorks Corp., Waltham, Mass., to allow one-step printing.

Using Industry 4.0 principles, the company is also working to provide more information all along the supply chain.

Taking advantage of the printers' jetting technology, which allows them to lay down extruded materials, as well as inks, voxel by voxel, the company also has announced a new Augmented Polymer Deposition (APD) process. The process allows parts to be marked with bar codes or QR codes as they're printed. The marks are intrinsic to the part, Reece said, and "can't be wiped off or worn off or scratched off."

That should be good news for Rize's primary customers — manufacturers in the defense, aerospace, pharmaceutical and medical sectors, where traceability is key.

Rize partner Cimquest Inc., Branchburg, N.J., will demonstrate APD, along with the RizeOne 3-D printer, in Booth S23147.

STRUCTUR3D

While the concept of Industry 4.0 often conjures up images of sensors and computers, Structur3D Printing CEO Charles Mire believes smart manufacturing provides something else: Freedom.

Founded in 2013, Structur3D makes an add-on for fused-deposition-modeling printers that allows them to print soft, paste-like materials, including silicone, epoxy, rubber and melted ABS.

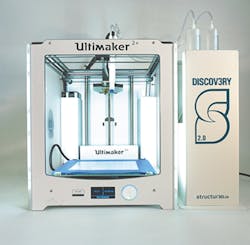

In Booth S230-13, Structur3D will show off the device that led to its founding, the one-material Discov3ry, as well as the Discov3ry 2.0, a coextrusion add-on system that's been available for only a few months. The technology allows printers to use an exponentially larger range of materials.

"We're sort of democratizing 3-D printing in a big way," Mire said.

Mire has designed the Discov3ry, as well as the Discov3ry 2.0, to work with Ultimaker printers — a platform he praised as reliable and robust. Ultimaker has one other characteristic he admires — it's open-source, which gives users the freedom to expand and experiment. Depending on users' printers, Mire said he can also provide customized retrofits. His primary customers include researchers and manufacturers that are experimenting with different materials.

3DCHIMERA

Customization and control.

Those are two key benefits that Alex Hussain, CEO of 3DChimera, which sells printers from a variety of OEMs and provides 3-D printing services, sees from Industry 4.0.

Among manufacturers, the 3-D printers 3DChimera sells are most often used for prototyping and in-house customization of items like jigs and end-of-arm tooling. But, Hussain said, customers also are starting to see the technology as a way to produce end-use parts. For him, being able to see inside the process is one of the most important features of new printers.

"Wasted material, lost print time, all these things can be prevented by being able to monitor the print job in real time," said Hussain, who noted that some printers now employ internal cameras.

The LAM, a liquid-silicone-rubber printer from German RepRap GmbH, Feldkirchen, Germany, that Hussain will show off at NPE, has no internal cameras, but it is designed to allow remote monitoring of characteristics such as print speed and extrusion speed. With remote monitoring, Hussain said users can mitigate problems and avoid mishaps, such as running out of filament mid-print.

Available through 3DChimera, the LAM will be displayed in Booth W4391, with support from M.R. Mold & Engineering Corp., Brea, Calif., and rubber industry supplier R.D. Abbott Co. Inc., Cerritos, Calif.

Phillip Britt, correspondent

Mikell Knights, senior staff reporter

Contact:

3DChimera,

Miami, 786-701-0700,www.3dchimera.com, www.germanreprap.com

Arburg Inc., Rocky Hill, Conn., 860-667-6500, www.arburg.com

Carbon Inc.,

Redwood City, Calif., 650-285-6307,www.carbon3d.com

HP Inc., Palo Alto, Calif., 650-857-1501, www.hp.com

Rize Inc.,

Woburn, Mass., 978-699-3085,www.rize3d.com

Stratasys Ltd.,

Eden Prairie, Minn., 952-937-3000,www.stratasys.com

Structur3D Printing,

Kitchener, Ontario, 888-407-5888,www.structur3d.io