Patent Report: Firm offers 3-D pultrusion system

A 3-D continuous-pultrusion printing system proposed by a California R&D company could be used to make complex parts without molds. The servo-motor-driven system, which would produce composites downstream of a heated die, includes a CNC controller, a material-advancement system and one or more 3-D thermoplastic-forming machines with thrusting and retracting plates attached to CNC actuators.

According to a patent issued to Ebert Composites Corp., Chula Vista, a chilled band would consolidate heated composite material into specific shapes as the material advanced.

"The 3-D thermoplastic pultrusion system continuously produces ... complex body panels such as doors and hoods, aircraft body panels, luggage compartments, airplane interior sections, aerodynamic surfaces, complex piping, duct-work, and any component that currently requires a large mold," the patent states.

The system could produce pultrusions with either varying cross-section geometries or varying surface contours, or both. Made from thermoplastic composite tapes, which are preheated in an oven, the material would consist of inside and outside sandwich skins and an interior core, with fibers threaded through all three layers. Patent 9,764,520; issued Sept. 19

In other patent news:

Film takeoff. Windmöller & Hölscher KG, Lengerich, Germany, has proposed an automated system to guide a blown film between a film blowing head and a takeoff roller device. The system improves upon time-consuming manual positioning as well as electric actuation methods.Because the company claims its method is more exact, the automated system will lead todecreased scrap rates. Patent 9,724,867; issued Aug. 8

Additive manufacturing. Thermwood Corp., Dale, Ind., has patented a device that combines a CNC machine with an extruder for forming 3-D objects. The extruder is mounted on the tool holder of a CNC machine that has a worktable. The extruder applies layers of thermoplastic onto the surface of the worktable to create an object. The invention features an improved extruder and applicator so that the products it creates require a minimal amount of machining to achieve the final shape, thus saving time and raw material. Patent 9,707,721; issued July 18

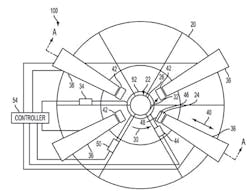

3-D printing. Xerox Corp., Norwalk, Conn., has invented a 3-D printer that features multiple print heads and builds objects on a rotating core. Many 3-D printers are slow, typically using a flat staging area onto which a single print head deposits layers of material by moving back and forth. The invention eliminates the need for the print head to repeatedly move across the stage to form the object, which results in faster printing, the patent states.The printer consists of a rotating cylinder, a frame, three print heads, multiple drives and a controller. The print heads eject material onto the outer surface of the cylinder, building layers as the surface rotates. In some embodiments, the print heads can eject different materials. Alternatively, it can be configured with multichannel print heads, each of which can eject multiple materials. Patent 9,701,064; issued July 11