Mazak machining center offers wire-arc-welding system

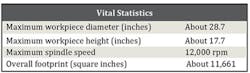

Variaxis j-600AM Mazak has launched a new vertical machining center that uses both additive and subtractive manufacturing methods to perform a wide variety of operations, including the production and repair of molds and dies. It features a C-axis indexing table and a B-axis tilt spindle that runs at 12,000 rpm. The center uses a wire-arc-welding head to deposit material layer by layer to grow near-net shapes; it then uses five-axis subtractive capabilities to produce high-precision parts.

What's new? The machining center, which the company introduced to the market late last year.

Benefits Cost-effective and efficient part machining. Because it uses wire instead of metal powder, the machining center deposits material quickly, and it uses raw materials more efficiently than systems that use only subtractive operations.

Mazak Corp., Florence, Ky., 859-342-1700, www.mazakusa.com